- #1

Frimkron

- 7

- 0

Hi everyone

I'm trying to write a computer simulation of meshing gears (actually its for a videogame), but my understanding of gears and torque is sadly lacking and I'm having trouble finding the answers to what I think are probably very basic questions. I apologise if I've posted this in the wrong place, by the way - it's my first time here.

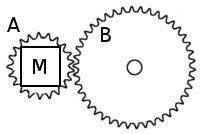

Firstly, let's suppose there are 2 connected gears of equal size, A and B. Motor M applies a torque to gear A, and we'll assume friction is negligable:

Am I correct in thinking that both gears are capable of delivering the same amount of torque that the motor is applying? At the same time?

Then we have the case of different gear ratios. Let's say that gear B has twice as many teeth as gear A:

I understand that the gear ratio means that gear B rotates at half the speed of gear A, but delivers twice the torque. Although I am not entirely sure why.

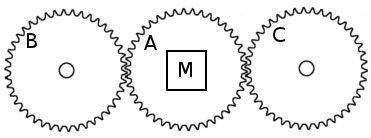

For a sequence of gears like this:

I can understand each gear delivering the same torque because I can sort of imagine that gear A applies all its force to gear B, which applies all its force to gear C.

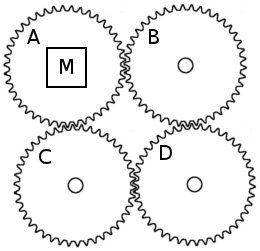

But what about this configuration:

Surely here gears B and C are only receiving half of A's force each. Does this mean B and C deliver half as much torque as A?

And following that line of reasoning:

Do gears B and C deliver half as much torque each as A or D? In other words does D deliver the same amount of torque as A, but B and C don't?

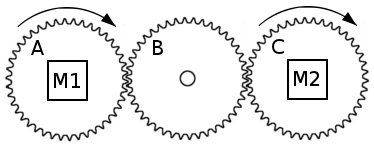

And with 2 motors, now, both applying torque in the same direction:

In this configuration would B deliver the torque of A and C combined?

I imagine I have misunderstood something fundamental here. If anyone could steer my thinking in the right direction I'd be very grateful.

I'm trying to write a computer simulation of meshing gears (actually its for a videogame), but my understanding of gears and torque is sadly lacking and I'm having trouble finding the answers to what I think are probably very basic questions. I apologise if I've posted this in the wrong place, by the way - it's my first time here.

Firstly, let's suppose there are 2 connected gears of equal size, A and B. Motor M applies a torque to gear A, and we'll assume friction is negligable:

Am I correct in thinking that both gears are capable of delivering the same amount of torque that the motor is applying? At the same time?

Then we have the case of different gear ratios. Let's say that gear B has twice as many teeth as gear A:

I understand that the gear ratio means that gear B rotates at half the speed of gear A, but delivers twice the torque. Although I am not entirely sure why.

For a sequence of gears like this:

I can understand each gear delivering the same torque because I can sort of imagine that gear A applies all its force to gear B, which applies all its force to gear C.

But what about this configuration:

Surely here gears B and C are only receiving half of A's force each. Does this mean B and C deliver half as much torque as A?

And following that line of reasoning:

Do gears B and C deliver half as much torque each as A or D? In other words does D deliver the same amount of torque as A, but B and C don't?

And with 2 motors, now, both applying torque in the same direction:

In this configuration would B deliver the torque of A and C combined?

I imagine I have misunderstood something fundamental here. If anyone could steer my thinking in the right direction I'd be very grateful.