- #1

becoming2000

- 2

- 0

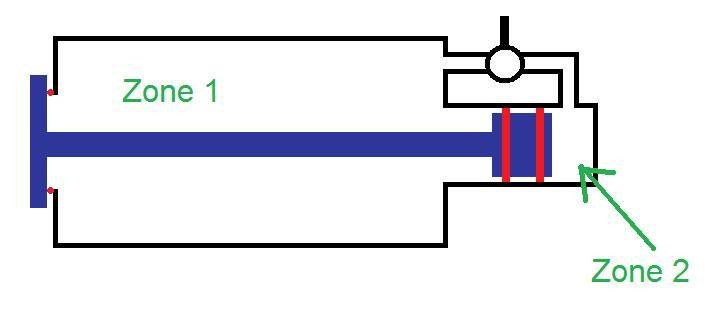

I'm in the process of designing a pneumatic air valve, and although I'm pretty sure I've got the concept down, I thought I'd run it by you to double check. Before I start explaining, here's a drawing that should give you a general idea of what I'm trying to accomplish.

There are a few things that aren't depicted in the drawing. Assume that everything outside of the valve is atmospheric pressure. Everything in red is a seal. The valve connecting Zone 1 to Zone 2 will be a 3-way valve, allowing Zone 2 to connect to Zone 1, or atmospheric pressure.

Under normal operation, you would fill Zone 1 with air. Zone 2 would be open to the same atmospheric pressure as the outlet side (far left). When you want to operate the valve, you would turn the small 3-way valve so that it closes Zone 2 from the atmosphere, and connects it to the pressurized Zone 1. The pressure in Zone 2 would push the piston forward, opening the outlet side.

If I understand this correctly, when Zone 2 is neutral, there will be a force exerted on the piston towards the outlet, due to the different sizes of each end of the piston. That force should be able to be calculated (roughly) using the Zone 1 pressure in psi, and the difference in area in square inches of each end of the piston, correct?

Assuming that's correct, I'll need to overcome that difference, and will most likely use a compressed spring. That will give me the added benefit of loosely regulating the maximum pressure in Zone 1, so my results will be better than random. The achieved pressure isn't really critical.

Keep in mind, nothing about this needs to be absolutely precise. It's only going to be used as a power source for a "water canon", to make a small version of the water shows you see at Las Vegas hotels. It'll be a blast for the kids this coming summer! I also need a lathe project for the winter, so I figured this would keep me busy for a couple days. Is this going to work as I've explained it, or is there something I need to plan differently?

There are a few things that aren't depicted in the drawing. Assume that everything outside of the valve is atmospheric pressure. Everything in red is a seal. The valve connecting Zone 1 to Zone 2 will be a 3-way valve, allowing Zone 2 to connect to Zone 1, or atmospheric pressure.

Under normal operation, you would fill Zone 1 with air. Zone 2 would be open to the same atmospheric pressure as the outlet side (far left). When you want to operate the valve, you would turn the small 3-way valve so that it closes Zone 2 from the atmosphere, and connects it to the pressurized Zone 1. The pressure in Zone 2 would push the piston forward, opening the outlet side.

If I understand this correctly, when Zone 2 is neutral, there will be a force exerted on the piston towards the outlet, due to the different sizes of each end of the piston. That force should be able to be calculated (roughly) using the Zone 1 pressure in psi, and the difference in area in square inches of each end of the piston, correct?

Assuming that's correct, I'll need to overcome that difference, and will most likely use a compressed spring. That will give me the added benefit of loosely regulating the maximum pressure in Zone 1, so my results will be better than random. The achieved pressure isn't really critical.

Keep in mind, nothing about this needs to be absolutely precise. It's only going to be used as a power source for a "water canon", to make a small version of the water shows you see at Las Vegas hotels. It'll be a blast for the kids this coming summer! I also need a lathe project for the winter, so I figured this would keep me busy for a couple days. Is this going to work as I've explained it, or is there something I need to plan differently?