- #1

StrSpeed

- 15

- 0

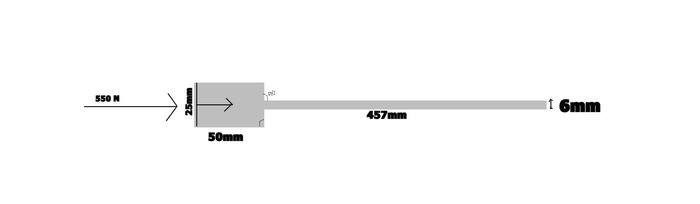

So recently I became more interested in CAD and i found myself drafting designs for spring airguns cylinders ect. All of-course meaningless given that I have zero understanding of the math behind the design. I am no Mechanical engineer, I am a business student so if I am getting into advanced stuff here let me know but I still intend on giving it my best..

/end rant/

Essentially I would like to understand how to calculate the pressure in a system when a Force of 550 Newtons is applied to it.

System volume: 37464

Piston(Right Cylinder) Volume: 24543 mm

Barrel(Right Cylinder) Volume: 12921mm

Change in Volume at piston peak: 24543

The gas inside the system is at sea level atmospheric pressure

I have also attached an image for reference!

if I am leaving anything out please let me know and Ill attempt to elaborate more!

/end rant/

Essentially I would like to understand how to calculate the pressure in a system when a Force of 550 Newtons is applied to it.

System volume: 37464

Piston(Right Cylinder) Volume: 24543 mm

Barrel(Right Cylinder) Volume: 12921mm

Change in Volume at piston peak: 24543

The gas inside the system is at sea level atmospheric pressure

I have also attached an image for reference!

if I am leaving anything out please let me know and Ill attempt to elaborate more!