- #1

chevinbrown

- 2

- 0

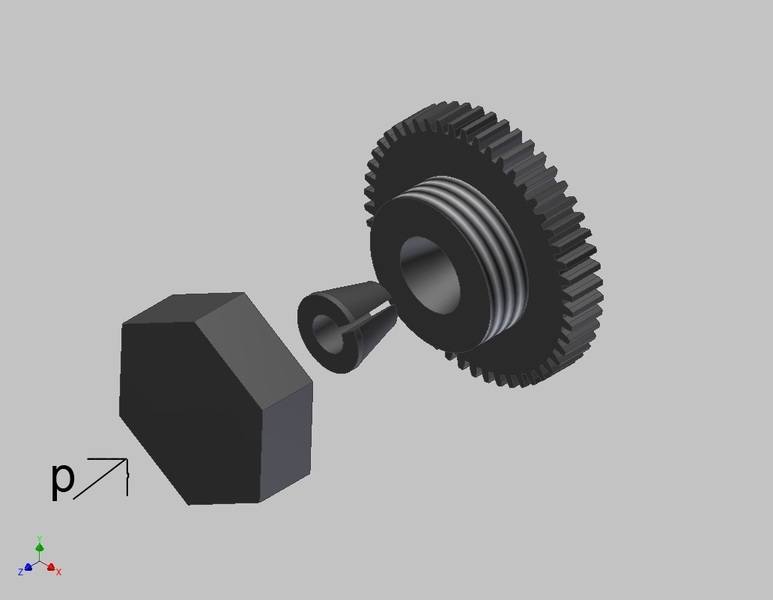

Gear Clamp Design--Describe Friction Force

I need to know how much frictional force is exerted on both sides of the collet (the piece in the middle of the image) when a force 'p' is applied by the cap nut.

(See attachment)

This is my first post here. Let me

know if I'm being too vague. :)

know if I'm being too vague. :)

I need to know how much frictional force is exerted on both sides of the collet (the piece in the middle of the image) when a force 'p' is applied by the cap nut.

(See attachment)

This is my first post here. Let me

Attachments

Last edited: