- #1

Nuckelavee

- 4

- 0

Hi everyone,

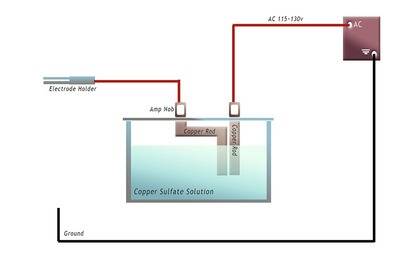

Some time ago i made a DIY AC Stick Welder, while i understand the basics of the machine, heat disipation, AC Arc and etc dynamics, I've some doubt i would like to clear before i proced with some modifications.

First ill attach its specs and diagram:

It works on simple 110~130v, 60hz at max of 50amps

I plan to modify it for Flux cored wire, but according to some ppl it only works on DC which i think its a "lazy answer", there has to be an equivalent on AC in terms of spark size and heat, I've read all about polarity and related stuff and i still don't get an smart complete answer.

Also id like to know what really happens chemically-wise in the water when mi machine is in use and the byproducts of it all.

Thanks in advance!

Some time ago i made a DIY AC Stick Welder, while i understand the basics of the machine, heat disipation, AC Arc and etc dynamics, I've some doubt i would like to clear before i proced with some modifications.

First ill attach its specs and diagram:

It works on simple 110~130v, 60hz at max of 50amps

I plan to modify it for Flux cored wire, but according to some ppl it only works on DC which i think its a "lazy answer", there has to be an equivalent on AC in terms of spark size and heat, I've read all about polarity and related stuff and i still don't get an smart complete answer.

Also id like to know what really happens chemically-wise in the water when mi machine is in use and the byproducts of it all.

Thanks in advance!