- #1

bdcrown007

- 16

- 0

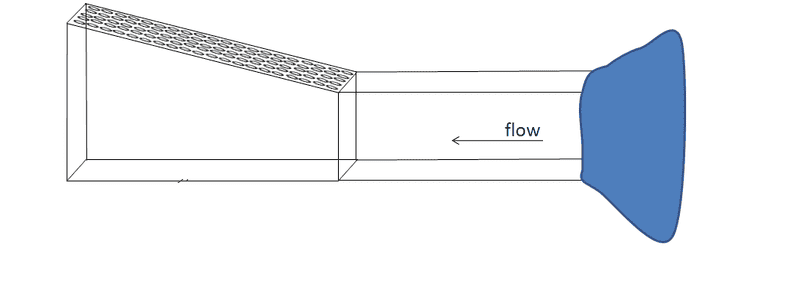

For my research purpose, I made a wind tunnel which has 0.6m rectangular section [0.2X0.2sq. meter] and 1.4m long diffuser section having porous top [top wall angle is 20deg] as follows:

Wind tunnel speed is 15m/s. Even using 20deg inclination of porous top wall, there is no flow separation over bottom plate. How can I produce flow separation on bottom plate? I also tested wind tunnel without any top wall at diffuser section on that case still no flow separation have been produced on bottom plate. Any idea?

One point should be noted that due to space limitation in our lab total length of tunnel [2m] could not be extended.

any idea please?

Wind tunnel speed is 15m/s. Even using 20deg inclination of porous top wall, there is no flow separation over bottom plate. How can I produce flow separation on bottom plate? I also tested wind tunnel without any top wall at diffuser section on that case still no flow separation have been produced on bottom plate. Any idea?

One point should be noted that due to space limitation in our lab total length of tunnel [2m] could not be extended.

any idea please?