- #1

DaveC426913

Gold Member

- 22,497

- 6,168

I have had a rocking chair in my basement for 20 years gifted to my by my father that I've never been able to repair.

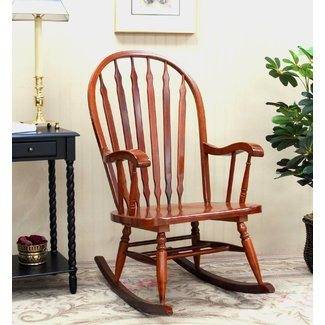

Its top-back rail has split and is in just the wrong place to mend. I'd like to wrap it in leather or sinew then let it dry and shrink to hold fast. Problem is, the central spine is right where the split is. It's this kind:

...but the central pillar is about 3" wide. It's split at the chair's highest point.

I'll take a pic and post it.

Its top-back rail has split and is in just the wrong place to mend. I'd like to wrap it in leather or sinew then let it dry and shrink to hold fast. Problem is, the central spine is right where the split is. It's this kind:

...but the central pillar is about 3" wide. It's split at the chair's highest point.

I'll take a pic and post it.