- #1

GRUMPYBLADE

- 5

- 0

Can anyone help?

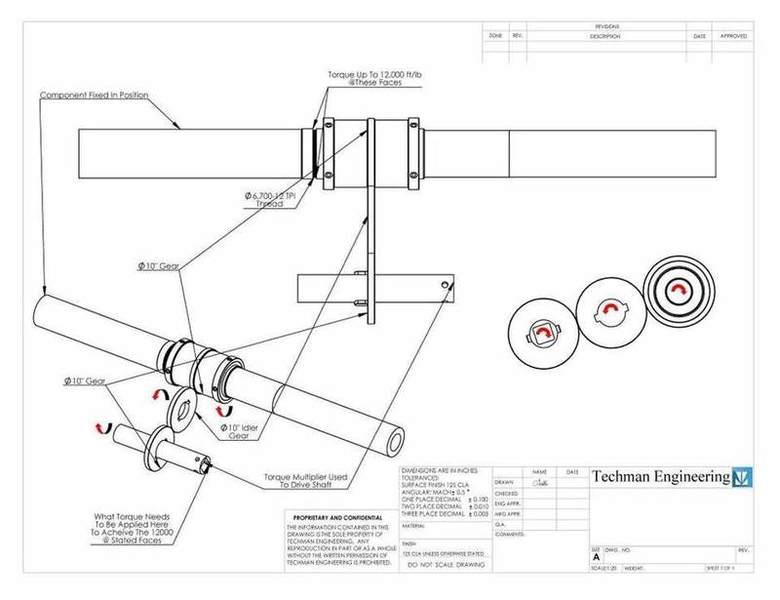

I need a calculation to find the force required @ the shaft indicated, to achieve torque indicated at the locating faces.

[/PLAIN]

[/PLAIN]

I need a calculation to find the force required @ the shaft indicated, to achieve torque indicated at the locating faces.