- #1

fitz_calc

- 41

- 0

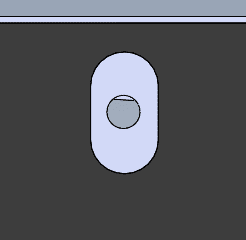

I have a part with a 2.5mm hole that sits inside a fixture (I need to verify hole presence), the hole can move anywhere around the slotted area due to part flexing, install force, etc.

One idea I had was point an 850nm InfraRed light from the other side at the hole, then mount an IR light sensor near the slot. Does an IR light sensor exist for an application like this? Any other ideas? Thanks!

One idea I had was point an 850nm InfraRed light from the other side at the hole, then mount an IR light sensor near the slot. Does an IR light sensor exist for an application like this? Any other ideas? Thanks!