- #1

charizzardd

- 6

- 0

Let me start off by saying I know it is not perpetual motion. I understand this. I was thinking about the fountain and was wondering if this arrangement would allow you to equalize the compartments and begin the process again, without having to flip the water compartments or pumping it up to the top cylinder again. You would have to open and close some valves...

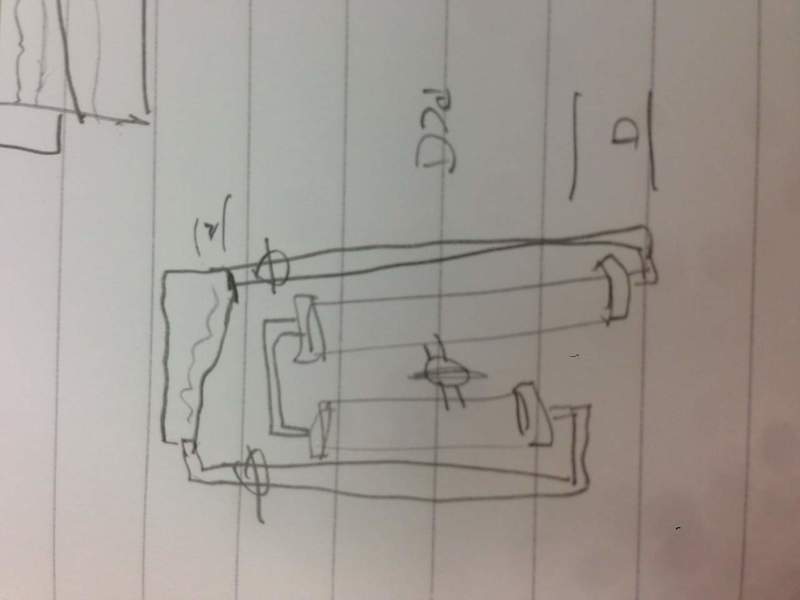

The system is set up as in the image...

Here is a diagram of a classic design of the fountain. The design I am proposing is similar but the tops of the two cylinders are at the same height, the bottom of one is just lower created the head difference. Adding a valve in between the two to allow for equalization.

Two side by side cylinders with a ball valve in between. As the shorter tube pushes water up the fountain, the water level decreases while the longer tubes water level increases. At some point the flow stops, or you close the outer ball valves in the lines going up to the fountain part. Then opening the middle ball valve would equalize the two cylinders. Upon closing the middle valve again and releasing water from the fountain, the process can start again...

The trick here being that the cylinder on the right is longer than the one on the left. The 'D' is the right cylinder distance below the left cylinder. 'd' is the distance the left cylinder output is higher than the right cylinder input. As long as 'd' is less than 'D' by enough distance to overcome head losses, the right cylinder water column will always be pushing against the one on the left through air pressure (connected at the top of the cylinders. When closing the outermost valves and opening the middle, the cylinders equalize the water height. Then when you close the middle and again open the outside valves, the flow should start again...

What do you think? Will closing the outer valves create some kind of vacuum preventing the water columns from equalizing? Sorry if my paragraph is repetitive...

The system is set up as in the image...

Here is a diagram of a classic design of the fountain. The design I am proposing is similar but the tops of the two cylinders are at the same height, the bottom of one is just lower created the head difference. Adding a valve in between the two to allow for equalization.

Two side by side cylinders with a ball valve in between. As the shorter tube pushes water up the fountain, the water level decreases while the longer tubes water level increases. At some point the flow stops, or you close the outer ball valves in the lines going up to the fountain part. Then opening the middle ball valve would equalize the two cylinders. Upon closing the middle valve again and releasing water from the fountain, the process can start again...

The trick here being that the cylinder on the right is longer than the one on the left. The 'D' is the right cylinder distance below the left cylinder. 'd' is the distance the left cylinder output is higher than the right cylinder input. As long as 'd' is less than 'D' by enough distance to overcome head losses, the right cylinder water column will always be pushing against the one on the left through air pressure (connected at the top of the cylinders. When closing the outermost valves and opening the middle, the cylinders equalize the water height. Then when you close the middle and again open the outside valves, the flow should start again...

What do you think? Will closing the outer valves create some kind of vacuum preventing the water columns from equalizing? Sorry if my paragraph is repetitive...