- #1

bdcrown007

- 16

- 0

Dear all,

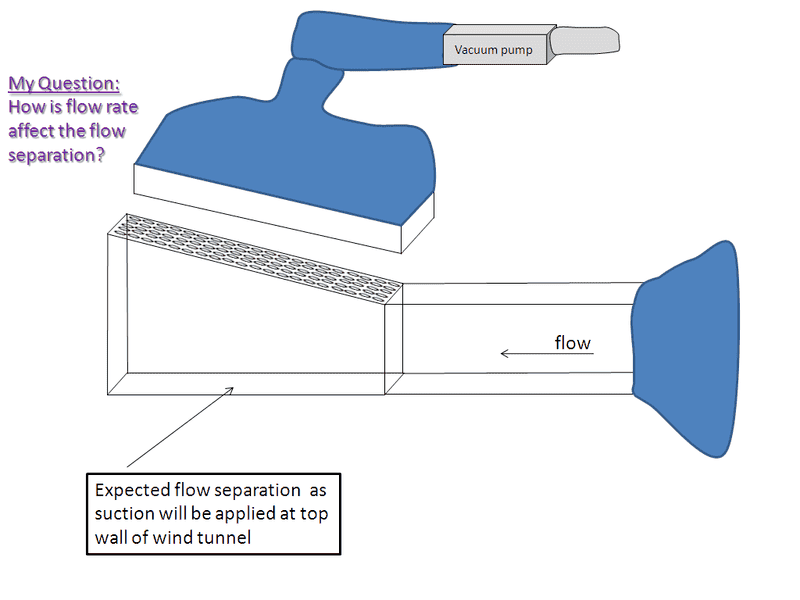

Take my best wishes. I am facing a problem designing my experimental setup for my research. I want to produce flow separation over a flat plate. Here is my experimental setup:

Diffuser angle is 16deg. I need some documentation/text book regarding the effect of suction flow rate over the flow separation. I read some papers those were describing flow separation on flat plate in wind tunnel, authors said that they applied suction over top plate to separate flow on bottom flat plate but I didn't find any more details on those papers...Can anyone help me? I need some theoretical approach and then based on that I will finalize my design. Help me please ASAP.

Thanking you

Take my best wishes. I am facing a problem designing my experimental setup for my research. I want to produce flow separation over a flat plate. Here is my experimental setup:

Diffuser angle is 16deg. I need some documentation/text book regarding the effect of suction flow rate over the flow separation. I read some papers those were describing flow separation on flat plate in wind tunnel, authors said that they applied suction over top plate to separate flow on bottom flat plate but I didn't find any more details on those papers...Can anyone help me? I need some theoretical approach and then based on that I will finalize my design. Help me please ASAP.

Thanking you

Last edited: