- #1

rollingstein

Gold Member

- 646

- 16

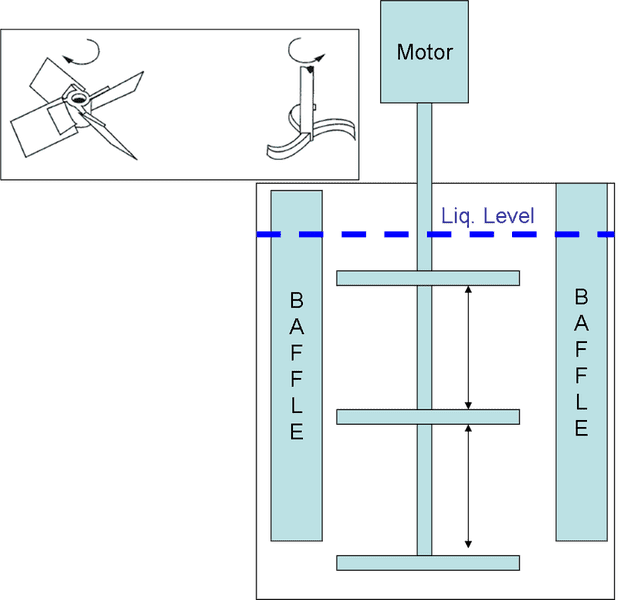

I've an impeller choice to make for a stirred tank reactor and would love some opinions. Essentially, I've a three level agitator as shown in the sketch I made. RPM is fixed (~85 rpm).

My real choice is only what combination of the two impeller designs I choose. Would you go for a pitched blade turbine in the middle (to provide axial flow) and two curved blade turbines at top and bottom to provide shear? Or all curved?

Any other ideas? I'd love to simulate this too (if this is a feasible proposition for a non-CFD expert). Overall I hope to have good circulation as well as a good phase mixing (i.e. droplet formation)

The fluid isn't very viscous (~10 cP) but has two immiscible phases (Specific Gravity difference ~0.1 gm/cc). Tank holds ~14,000 Litres and has a 30 hP motor.

PS. If a mod can resize the IMG tag that'd help me! Not sure what attributes it takes.

My real choice is only what combination of the two impeller designs I choose. Would you go for a pitched blade turbine in the middle (to provide axial flow) and two curved blade turbines at top and bottom to provide shear? Or all curved?

Any other ideas? I'd love to simulate this too (if this is a feasible proposition for a non-CFD expert). Overall I hope to have good circulation as well as a good phase mixing (i.e. droplet formation)

The fluid isn't very viscous (~10 cP) but has two immiscible phases (Specific Gravity difference ~0.1 gm/cc). Tank holds ~14,000 Litres and has a 30 hP motor.

PS. If a mod can resize the IMG tag that'd help me! Not sure what attributes it takes.

Last edited: