- #1

mess

- 59

- 8

- TL;DR Summary

- I would like to consider building a heat exchanger for my campervan. In Canada it can get as cold as -40 where I will be travelling to, I would like to see how much energy/fuel ill be saving with my heater by doing so, to determine if its worth building.

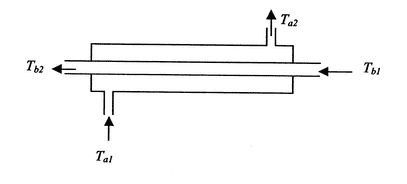

I am considering building this type of heat exchanger, as I have seen several youtube videos on the build. The inside tube is aluminum,

I am planning on building one from the top of my roof to nearly the floor, so ill say 5 feet. I am thinking of using a 1.5" inch aluminum tube, and bringing in 15CFM of fresh cold air per person, and the out pipe surrounding the in pipe will consequently be removing 15CFM. Assuming its just 20CFM for me and my puppy at the moment.

I calculated the surface area is 580 in^3 for that inside aluminum pipe.

I see that aluminum has a heat conductivity of 205.0 w/mK.

I think the pipe will be about 1mm in thickness if I was to guess.

The inside temperature should be 21C, and the outside ide like to calculate for -5 for now.

Thats all the data I feel is needed, though I am not sure what formula to use, and it gets complicated to me because the in-pipe will be flowing cold at 15CFM, while the out-pipe will be flowing hot at 15CFM. Also there is some equilibrium across that surface area between the in and out temperatures at some point, to some degree, which makes it even more complicated (calculus?).

Any suggestions on how I can go about calculating this?

This is all just for fun and exploring science and the world :D

I am planning on building one from the top of my roof to nearly the floor, so ill say 5 feet. I am thinking of using a 1.5" inch aluminum tube, and bringing in 15CFM of fresh cold air per person, and the out pipe surrounding the in pipe will consequently be removing 15CFM. Assuming its just 20CFM for me and my puppy at the moment.

I calculated the surface area is 580 in^3 for that inside aluminum pipe.

I see that aluminum has a heat conductivity of 205.0 w/mK.

I think the pipe will be about 1mm in thickness if I was to guess.

The inside temperature should be 21C, and the outside ide like to calculate for -5 for now.

Thats all the data I feel is needed, though I am not sure what formula to use, and it gets complicated to me because the in-pipe will be flowing cold at 15CFM, while the out-pipe will be flowing hot at 15CFM. Also there is some equilibrium across that surface area between the in and out temperatures at some point, to some degree, which makes it even more complicated (calculus?).

Any suggestions on how I can go about calculating this?

This is all just for fun and exploring science and the world :D