friscoboya

- 6

- 1

Hello,

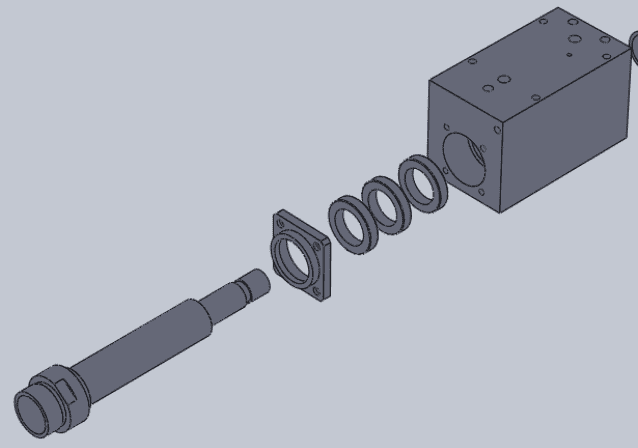

So I am designing a shaft which would involve bearings on the shaft, and a housing which would enclose the shaft. The shaft would be slightly bigger than the bearing hole which would create an interference fit so the bearings would stay on the shaft tightly. At the same time the bearing and shaft would be placed in a housing where the housing holes would be slightly smaller than the bearing outer diameter which would provide a tight fit so the bearings would stay in place. How would I determine the tolerance for the appropriate desired bearing stiffness? Below is a picture.

Thanks

Thanks

So I am designing a shaft which would involve bearings on the shaft, and a housing which would enclose the shaft. The shaft would be slightly bigger than the bearing hole which would create an interference fit so the bearings would stay on the shaft tightly. At the same time the bearing and shaft would be placed in a housing where the housing holes would be slightly smaller than the bearing outer diameter which would provide a tight fit so the bearings would stay in place. How would I determine the tolerance for the appropriate desired bearing stiffness? Below is a picture.