- #1

Chad Gilchrist

- 2

- 0

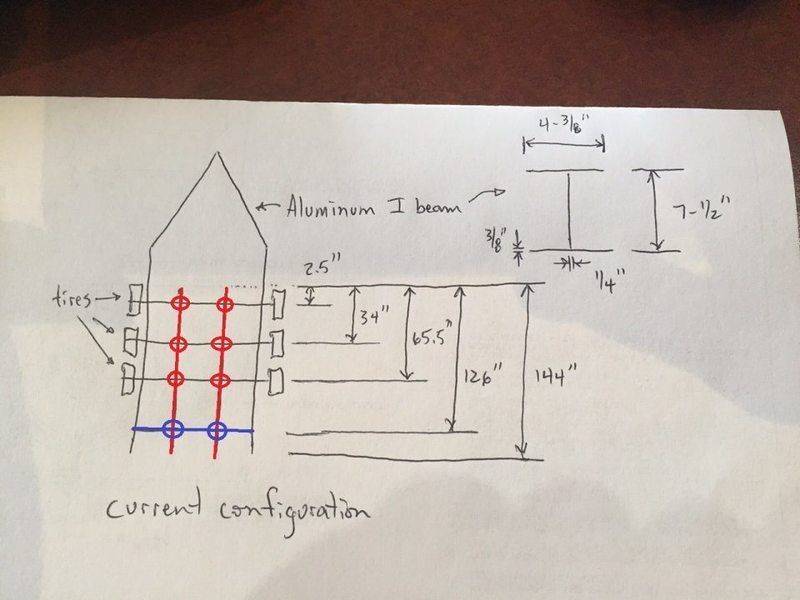

I need a little help on the redesign of our boat trailer, if you guys wouldn't mind giving a little advice. We have a heavy boat [we can assume the boat is 20,000 lbs], and we need to 1] increase the capacity of our axles, and 2] redistribute the loading of the weight. Currently, the weight of the boat is mainly carried directly on the axles. I would like to redistribute the weight to the main aluminum I beams on each side of the trailer, and then support the I beams with the axles. That will move the loading further to the outside of the axles, where they are better able to support the weight. Right now, the loading is too close to the center of the axle, causing them to bow too much. I made rough sketches of the trailer configuration for reference.

The red lines are the bungs that the boat sit on. The red circles are where the bungs are U bolted to the axles. The axles are 3" square steel tubes. The blue line is a 3" square aluminum tube that also supports the bungs, and the bungs are U bolted to this tube at the blue circles.

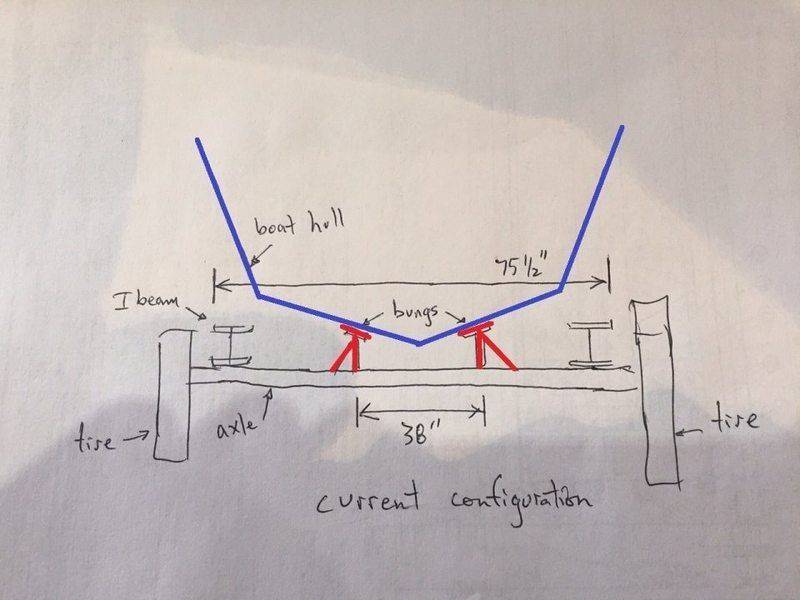

This is an end view, showing the loading of the bungs on the axles. We have to have the bungs in this position, due to water intakes and other features on the bottom of the hull. As you can see, this load should be positioned closer to the wheels in order to allow the axles to correctly support the load.

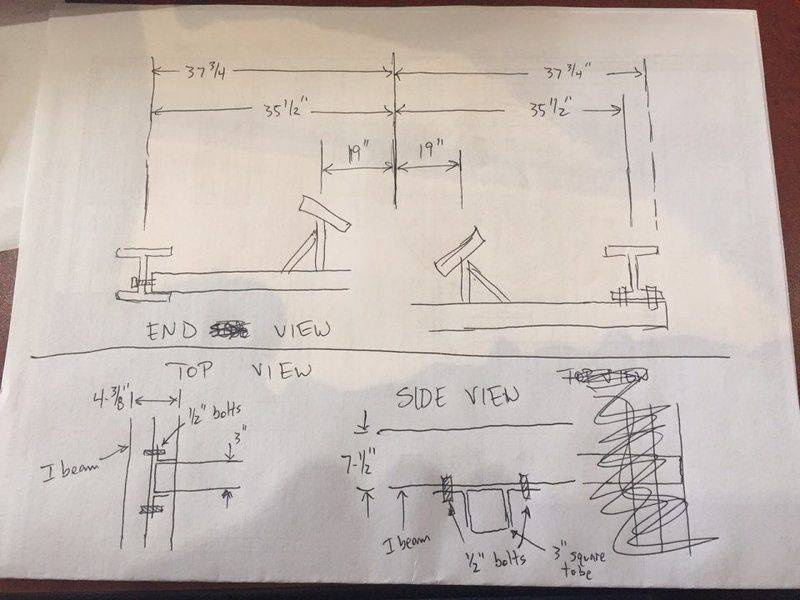

I would like to design, fab, and install 5 supports across the I beams for the bungs, and completely remove the bungs from the axles. Then I will support the I beams with the 3 axles. The new supports will need to be 3" square tubes, so the bungs will easily bolt up. Here are two possible ways to move the loading to the I beams. One is to run the new square support tube under the I beam, weld a piece of angle on each side, and thru bolt it to the underside of the I beam. The other is to run the new square support tube to the inside of the I beam, let the bottom of the beam support this tube, and weld a piece of angle on each side to bolt it thru the center vertical piece of the I beam. I am not sure which method would be stronger.

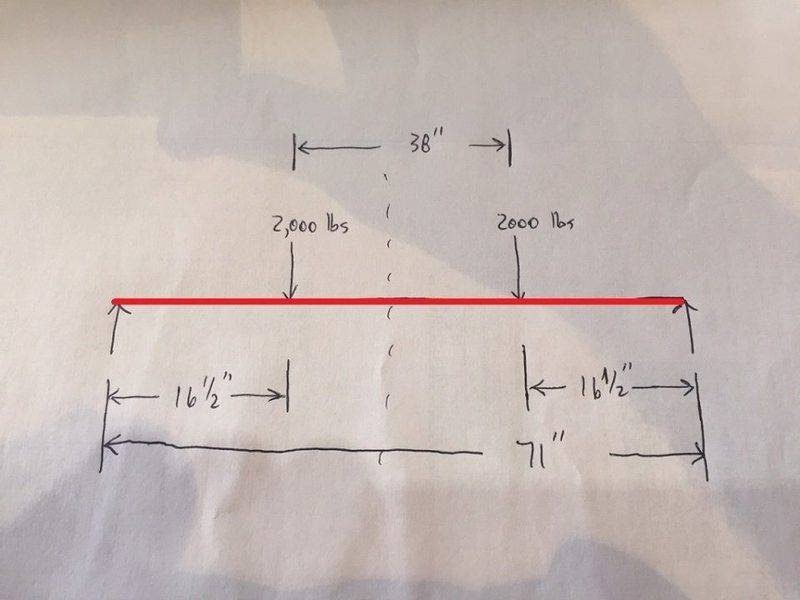

Assuming the boat is 20,000, and that we have 5 support beams, and that each beam supports the boat at two positions, I feel the problem can be summarized by the sketch below, where the red line is the new square suppport tube.

My questions revolve around what this tube needs to be to handle the loading. I would prefer aluminum, if it is strong enough, for the corrosion resistance. Can I go with 3" square aluminum tube with a 0.25" wall thickness? Do I need 0.375" wall? Or maybe even 0.500" wall? Should I steel for more strength?

Also, if I bolt the new tube underneath the I beam, the entire load will be supported by stainless steel cap screws. There will be 4 cap screws on each end of the support tube, supporting the 2000 lbs. What will 4 cap screws be able to support, if they are 1/2"? Should they be 5/8"? Or will it be significantly better to rest the end of the support tube on top of the bottom plate of the I beam?

The red lines are the bungs that the boat sit on. The red circles are where the bungs are U bolted to the axles. The axles are 3" square steel tubes. The blue line is a 3" square aluminum tube that also supports the bungs, and the bungs are U bolted to this tube at the blue circles.

This is an end view, showing the loading of the bungs on the axles. We have to have the bungs in this position, due to water intakes and other features on the bottom of the hull. As you can see, this load should be positioned closer to the wheels in order to allow the axles to correctly support the load.

I would like to design, fab, and install 5 supports across the I beams for the bungs, and completely remove the bungs from the axles. Then I will support the I beams with the 3 axles. The new supports will need to be 3" square tubes, so the bungs will easily bolt up. Here are two possible ways to move the loading to the I beams. One is to run the new square support tube under the I beam, weld a piece of angle on each side, and thru bolt it to the underside of the I beam. The other is to run the new square support tube to the inside of the I beam, let the bottom of the beam support this tube, and weld a piece of angle on each side to bolt it thru the center vertical piece of the I beam. I am not sure which method would be stronger.

Assuming the boat is 20,000, and that we have 5 support beams, and that each beam supports the boat at two positions, I feel the problem can be summarized by the sketch below, where the red line is the new square suppport tube.

My questions revolve around what this tube needs to be to handle the loading. I would prefer aluminum, if it is strong enough, for the corrosion resistance. Can I go with 3" square aluminum tube with a 0.25" wall thickness? Do I need 0.375" wall? Or maybe even 0.500" wall? Should I steel for more strength?

Also, if I bolt the new tube underneath the I beam, the entire load will be supported by stainless steel cap screws. There will be 4 cap screws on each end of the support tube, supporting the 2000 lbs. What will 4 cap screws be able to support, if they are 1/2"? Should they be 5/8"? Or will it be significantly better to rest the end of the support tube on top of the bottom plate of the I beam?