- #1

Eagle9

- 238

- 10

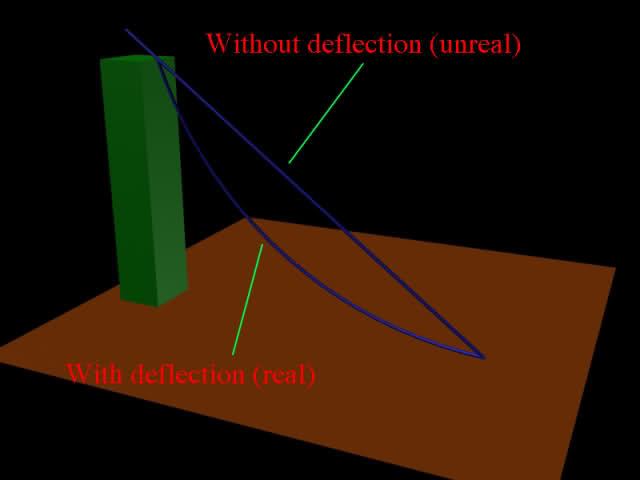

Here we have got tall building standing on the ground and long rod. Rod’s one end is placed on the ground and the second one-on the building.

Surely, the rod will be deflected due to its own weight and Earth’s gravity. Can we calculate the value of deflection if we know rod’s end, its material’s property (Young’s modulus), length, radius and etc?

Surely, the rod will be deflected due to its own weight and Earth’s gravity. Can we calculate the value of deflection if we know rod’s end, its material’s property (Young’s modulus), length, radius and etc?