- #1

gary350

- 253

- 52

- TL;DR Summary

- FUN induction heater circuit.

If you have not built an induction heater yet it is a fun project. Build the small circuit with 6 yellow capacitors first.

Induction heater is a fun project. I built a small induction heater then I wanted a more powerful one. A small unit is so simple you can build it in about 2 hours work. A larger more powerful unit will take longer. If you take your induction camping it works great to run it on your 12v car battery.

I built my largest induction heater from a microwave oven transformer. Remove the 2000v secondary coil, replace it with enough #12 solid copper wire to get 12v to 15vdc. I have about 15 MOTs they all have 100 turns on the primary coil. Math is easy for the secondary coil running on 120vac on the primary = about .833 vac per turn on the secondary.

I have not experimented with a flat induction coil the value must be 2. uh minimum value. Buy a, resistor, capacitor, inductor, meter about $35. on ebay to test your coils. The choke coil needs to be large enough not to saturate or it will stop working at a certain power range then current suddenly goes to maximum then mosfets explode. Very low internal mosfet resistance works best it prevents mosfets from over heating easy.

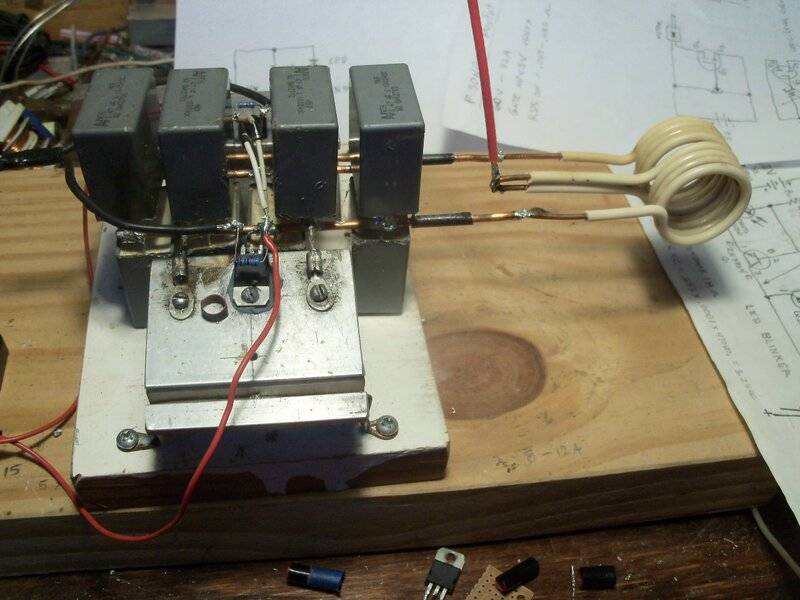

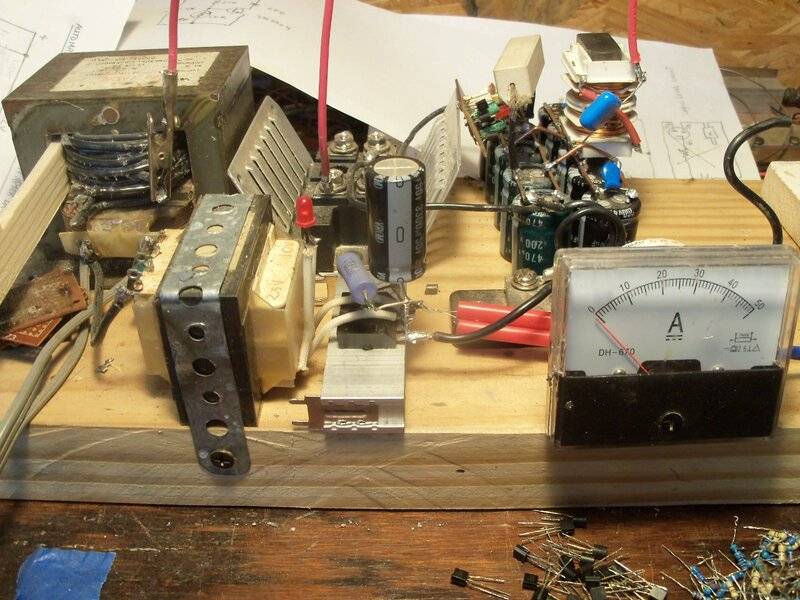

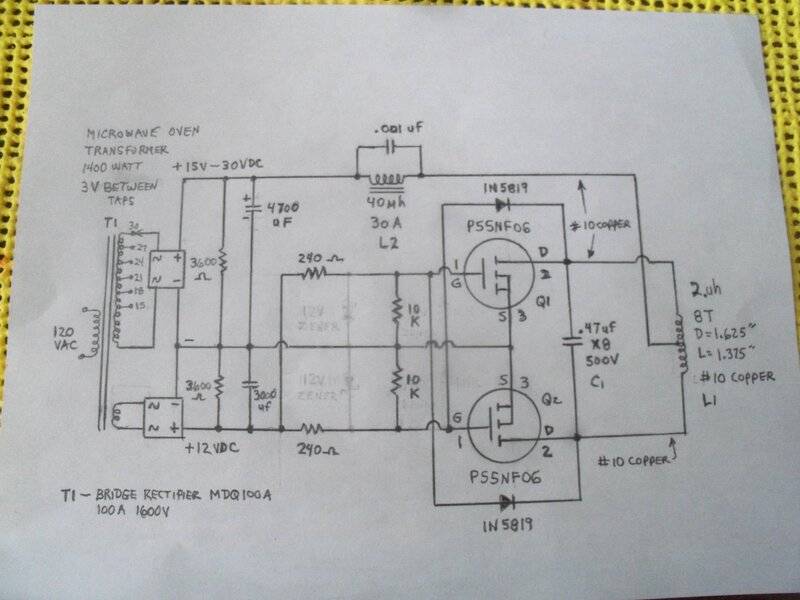

Here is my induction circuit, leave off the transformers so you can run it on a car battery if that is what you want. My small induction heater will heat a 1/4" steel rod red hot in about 3 minutes. My 1400w induction heater heats a 1/4" steel rod red hot in 7 seconds. You don't need 1400w to heat food it will burn before food has time to cook.

My induction heaters all have the same circuit drawing for the exception of larger power supplies and larger L2 choke coil for higher power units. If you change #10 circuit copper wire to a smaller wire skin effect goes up and the circuit efficiency goes down. My induction heat is several times smaller than the 1400w power supply as you can see in the photos.

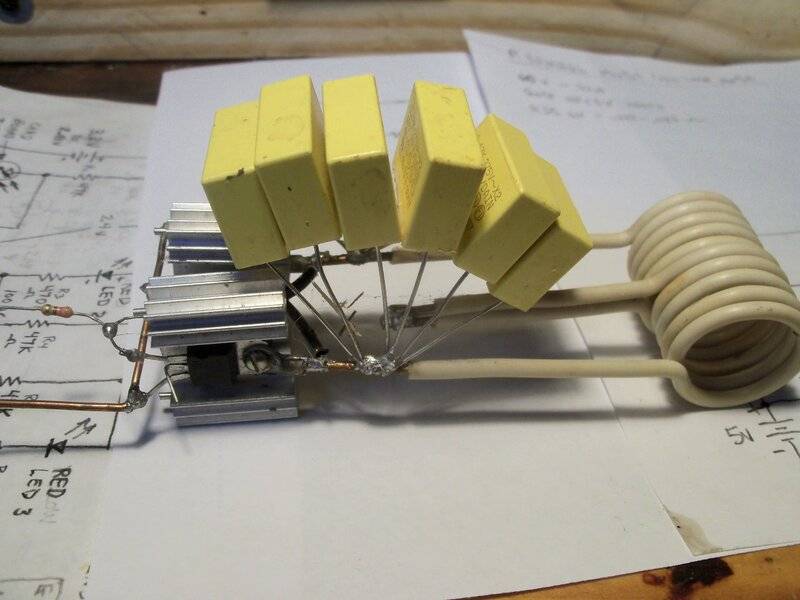

Be sure to connect the caps in a box shape like a Rail Gun cap bank charge and discharge is much faster. Build the small unit with the 6 yellow color caps first. I use insulated Romex solid copper house wire. Be sure to use insulated wire if you accidently touch the osc coil with metal osc stops then 1 of the mosfets will explode.

You can build the small circuit for $15. The larger circuit only cost be extra for a 100a bridge rectifier and the meter. I salvage parts from old TV and old computer power supplies. 10 mosfets are $6 free shipping on ebay if you order from a seller in China.

Induction heater is a fun project. I built a small induction heater then I wanted a more powerful one. A small unit is so simple you can build it in about 2 hours work. A larger more powerful unit will take longer. If you take your induction camping it works great to run it on your 12v car battery.

I built my largest induction heater from a microwave oven transformer. Remove the 2000v secondary coil, replace it with enough #12 solid copper wire to get 12v to 15vdc. I have about 15 MOTs they all have 100 turns on the primary coil. Math is easy for the secondary coil running on 120vac on the primary = about .833 vac per turn on the secondary.

I have not experimented with a flat induction coil the value must be 2. uh minimum value. Buy a, resistor, capacitor, inductor, meter about $35. on ebay to test your coils. The choke coil needs to be large enough not to saturate or it will stop working at a certain power range then current suddenly goes to maximum then mosfets explode. Very low internal mosfet resistance works best it prevents mosfets from over heating easy.

Here is my induction circuit, leave off the transformers so you can run it on a car battery if that is what you want. My small induction heater will heat a 1/4" steel rod red hot in about 3 minutes. My 1400w induction heater heats a 1/4" steel rod red hot in 7 seconds. You don't need 1400w to heat food it will burn before food has time to cook.

My induction heaters all have the same circuit drawing for the exception of larger power supplies and larger L2 choke coil for higher power units. If you change #10 circuit copper wire to a smaller wire skin effect goes up and the circuit efficiency goes down. My induction heat is several times smaller than the 1400w power supply as you can see in the photos.

Be sure to connect the caps in a box shape like a Rail Gun cap bank charge and discharge is much faster. Build the small unit with the 6 yellow color caps first. I use insulated Romex solid copper house wire. Be sure to use insulated wire if you accidently touch the osc coil with metal osc stops then 1 of the mosfets will explode.

You can build the small circuit for $15. The larger circuit only cost be extra for a 100a bridge rectifier and the meter. I salvage parts from old TV and old computer power supplies. 10 mosfets are $6 free shipping on ebay if you order from a seller in China.

Last edited: