- #1

paulzhen

- 33

- 0

Hi!

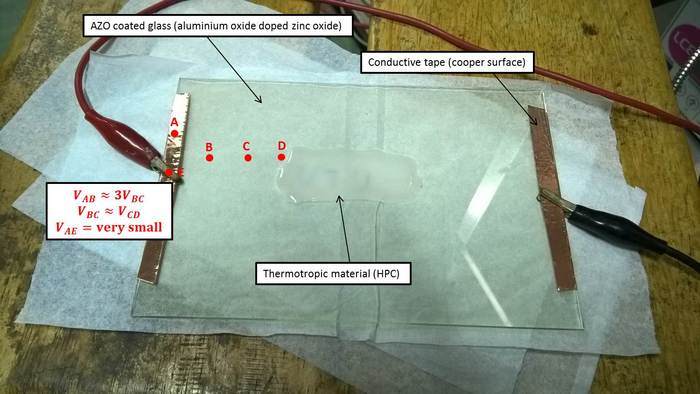

I tried to heat the AZO conductive glass with a current source = 0.5A.

However, I found the voltage near the contact points was almost 3 times higher than that on the glass surface (please see the picture for details). It means the heating effect mainly happened near the contact points, very slow heating at the middle of the glass.

I check and did my best to keep good contacts between all components, and I have tried several different ways to make contacts including stick the exposed conducting wire directly onto the cooper tape or the surface of the glass, but the results are pretty much the same (heating still mainly happened near the contacts)!

Please someone explain to me what went wrong, and what would you recommend if I want to achieve an uniform and fast heating effect on AZO glass.

Thanks so much!

I tried to heat the AZO conductive glass with a current source = 0.5A.

However, I found the voltage near the contact points was almost 3 times higher than that on the glass surface (please see the picture for details). It means the heating effect mainly happened near the contact points, very slow heating at the middle of the glass.

I check and did my best to keep good contacts between all components, and I have tried several different ways to make contacts including stick the exposed conducting wire directly onto the cooper tape or the surface of the glass, but the results are pretty much the same (heating still mainly happened near the contacts)!

Please someone explain to me what went wrong, and what would you recommend if I want to achieve an uniform and fast heating effect on AZO glass.

Thanks so much!

Last edited: