- #1

Cutlynx

- 10

- 0

hello, first i would like to say, even through i enjoy working with SolidWorks, I am not an engineer. so any more technical stuff may go over my head, and everyone who would help me even through that disadvantage have my eternal gratitude.

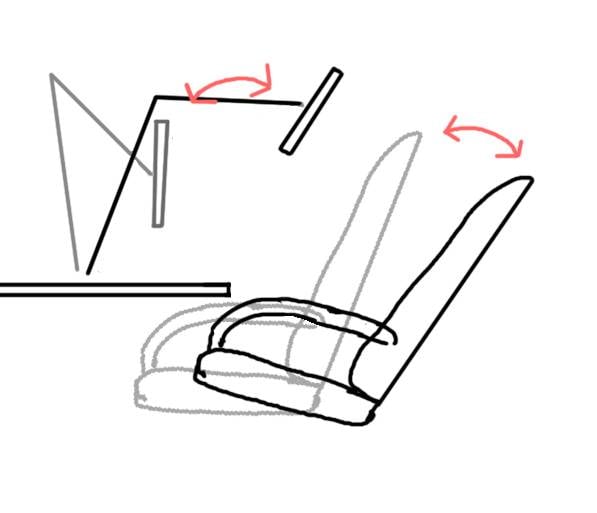

my home project was made because of whole monitor stand market dissatisfaction. i want monitor stand with much more wider range to offer at least theese two setings:

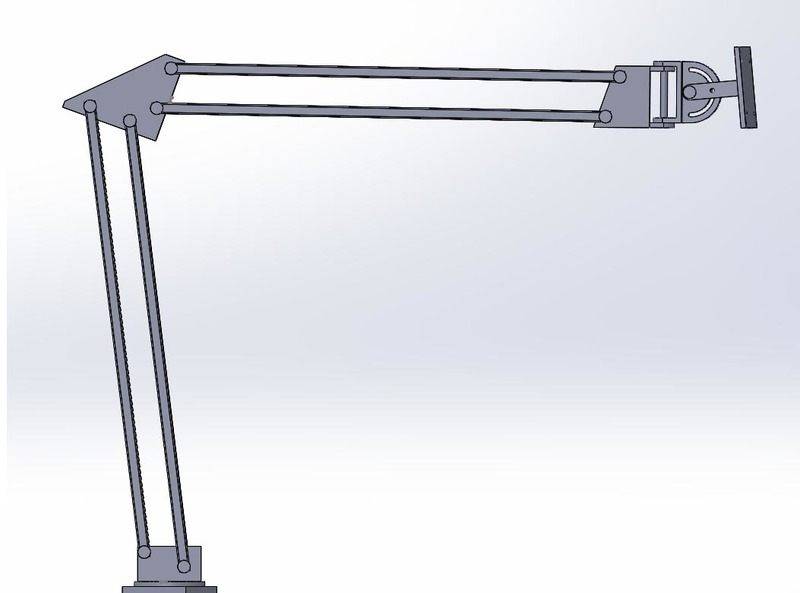

so this is my model so far (whole model is in spring-arm.zip). i tried to put it into simulation with spring but it violently exploded

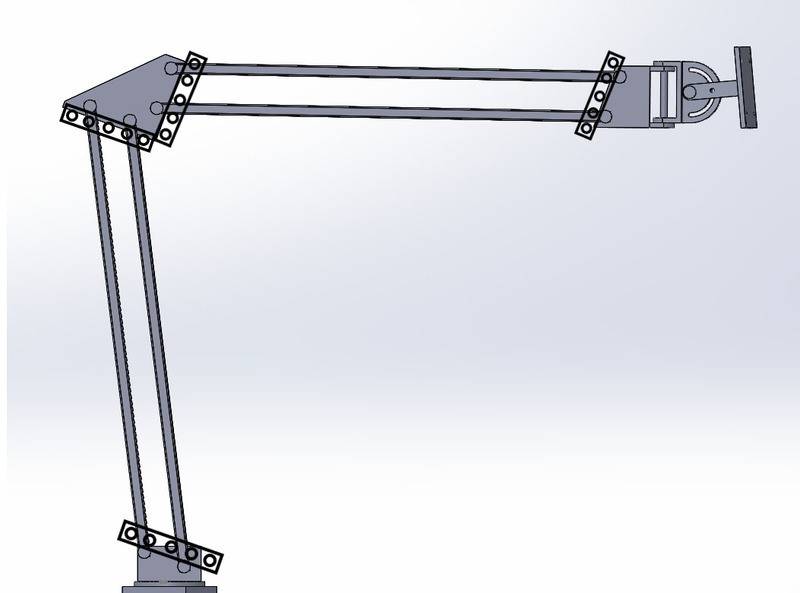

i thought to put in there some holed plates like this to just hopefully find the right way after its build.

i thought to put in there some holed plates like this to just hopefully find the right way after its build.

my idea is to just connect it with spring and wire-tensor and figure out the right pull on run.

but I am quite nervous ill won't manage it. so I am asking you for any questions what would be your idea how to pull this off.

my home project was made because of whole monitor stand market dissatisfaction. i want monitor stand with much more wider range to offer at least theese two setings:

so this is my model so far (whole model is in spring-arm.zip). i tried to put it into simulation with spring but it violently exploded

my idea is to just connect it with spring and wire-tensor and figure out the right pull on run.

but I am quite nervous ill won't manage it. so I am asking you for any questions what would be your idea how to pull this off.