- #36

Baluncore

Science Advisor

2023 Award

- 14,394

- 8,287

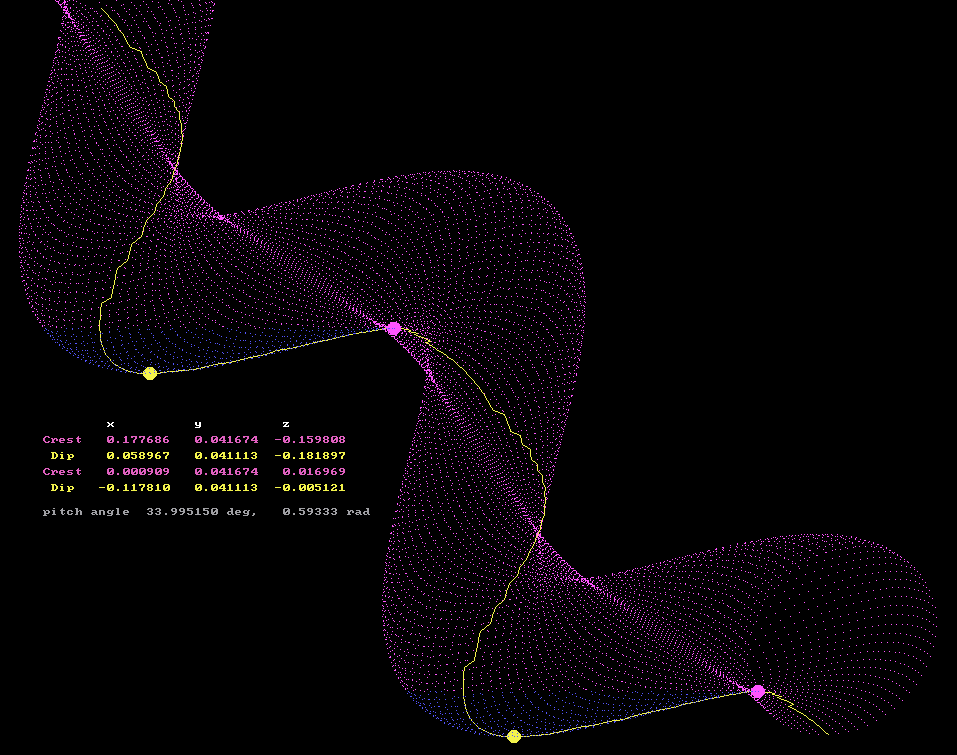

Here is a view of your helical tube.

X is to the right. Y is away from viewer. Z is up.

Helix axis passes through origin at angle of 45°.

Yellow line is valley. Yellow circle is where ball will rest in dip.

Magenta circle is a crest. Blue is volume that will hold a liquid.

X is to the right. Y is away from viewer. Z is up.

Helix axis passes through origin at angle of 45°.

Yellow line is valley. Yellow circle is where ball will rest in dip.

Magenta circle is a crest. Blue is volume that will hold a liquid.