- #1

Purple_Dan

- 47

- 4

Hello all,

The root problem is that I can't put all my analogue inputs onto one input card (each card has 4 inputs) on the project I'm working on.

We have four sensors, they should all output 4-20mA.

Two are source type outputs, supply voltage goes in, sensor current comes out, current is measured between sensor output and ground.

The other two are sink type outputs. I believe they're outputting 4-20mA, but with reference to the power supply rather than with reference to ground. They appear to work when you put the supply power into the input and use the sensor output as the ground.

On to the next problem.

These cards have four inputs, but use a common ground. This means that I can have the two source type sensors on one card, but I'll need a separate card for each of the two sink type sensors.

We only have 2 cards, and the client doesn't want to buy more. They're also not keen on hiring an Electrical Engineer to do it properly. Things are quiet in the office at the moment so I'm spending my spare time hypothesising.

Possible solutions:

The cards only sense current flowing one way. If I could reverse the current, I could put the supply on the ground terminal and the sensor output into the card input. I think this will be difficult/impossible/potentially damaging to equipment.

I believe the sink type sensor is outputting the supply current - (4-20mA). For example, if the supply current is 600mA, then the sensor is outputting 580-596mA (20-4mA). If I could take off 576mA from the sensor current I would be left with 4-20mA with respect to ground. 20mA would be detected as 4mA and vice versa, but I can deal with that in the programming.

I thought about putting a resistor in parallel, but found that I would need different resistances depending on the output of the sensor to take off 576mA each time. And a controllable variable resistor would just add more complexity.

I should mention that, while I did Robotics Engineering at Uni, my strong suit is in software. So if it sounds like you're reading a bunch of nonsense, you probably are.

The input card is a "Crevis ST-3234", here's a link to the pdf:

https://www.google.co.uk/url?sa=t&r...=_n--ZSnP6G-bSvX22HpgsA&bvm=bv.99556055,d.ZGU

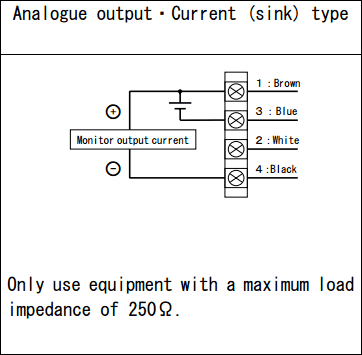

The sensor output looks like this:

The power supply is 24v, I don't know the current or the internal resistance of the supply.

As you can see from the picture, the +24v is going to the input of the card and the output of the sensor (4: Black) is going to the ground of the card.

Thanks for any light you can shed on the subject.

Dan

The root problem is that I can't put all my analogue inputs onto one input card (each card has 4 inputs) on the project I'm working on.

We have four sensors, they should all output 4-20mA.

Two are source type outputs, supply voltage goes in, sensor current comes out, current is measured between sensor output and ground.

The other two are sink type outputs. I believe they're outputting 4-20mA, but with reference to the power supply rather than with reference to ground. They appear to work when you put the supply power into the input and use the sensor output as the ground.

On to the next problem.

These cards have four inputs, but use a common ground. This means that I can have the two source type sensors on one card, but I'll need a separate card for each of the two sink type sensors.

We only have 2 cards, and the client doesn't want to buy more. They're also not keen on hiring an Electrical Engineer to do it properly. Things are quiet in the office at the moment so I'm spending my spare time hypothesising.

Possible solutions:

The cards only sense current flowing one way. If I could reverse the current, I could put the supply on the ground terminal and the sensor output into the card input. I think this will be difficult/impossible/potentially damaging to equipment.

I believe the sink type sensor is outputting the supply current - (4-20mA). For example, if the supply current is 600mA, then the sensor is outputting 580-596mA (20-4mA). If I could take off 576mA from the sensor current I would be left with 4-20mA with respect to ground. 20mA would be detected as 4mA and vice versa, but I can deal with that in the programming.

I thought about putting a resistor in parallel, but found that I would need different resistances depending on the output of the sensor to take off 576mA each time. And a controllable variable resistor would just add more complexity.

I should mention that, while I did Robotics Engineering at Uni, my strong suit is in software. So if it sounds like you're reading a bunch of nonsense, you probably are.

The input card is a "Crevis ST-3234", here's a link to the pdf:

https://www.google.co.uk/url?sa=t&r...=_n--ZSnP6G-bSvX22HpgsA&bvm=bv.99556055,d.ZGU

The sensor output looks like this:

The power supply is 24v, I don't know the current or the internal resistance of the supply.

As you can see from the picture, the +24v is going to the input of the card and the output of the sensor (4: Black) is going to the ground of the card.

Thanks for any light you can shed on the subject.

Dan