- #1

HerrWitz

- 1

- 0

Hi all,

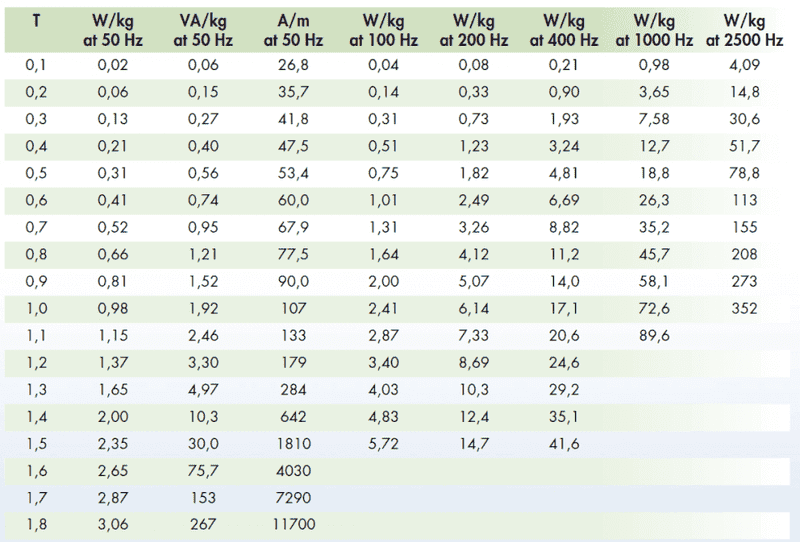

I am recently calculating the iron loss in a permanent magnet synchronous machine with a speed of 24000 rpm (electrical frequency 800 Hz). However, the iron loss data from the data sheet is not sufficient since only frequency of 50 Hz, 100 Hz, 200 Hz, 400 Hz, 1000 Hz and 2500 Hz are given.

To calculate the iron loss, up to 13th harmonic (10400 Hz) has to be considered in this case. Since there is no prototype machine available, is there a way (e.g. curve fitting) to estimate the iron loss data in higher frequencies?

Thank you!

I am recently calculating the iron loss in a permanent magnet synchronous machine with a speed of 24000 rpm (electrical frequency 800 Hz). However, the iron loss data from the data sheet is not sufficient since only frequency of 50 Hz, 100 Hz, 200 Hz, 400 Hz, 1000 Hz and 2500 Hz are given.

To calculate the iron loss, up to 13th harmonic (10400 Hz) has to be considered in this case. Since there is no prototype machine available, is there a way (e.g. curve fitting) to estimate the iron loss data in higher frequencies?

Thank you!

Last edited: