- #1

Euan12345

- 11

- 0

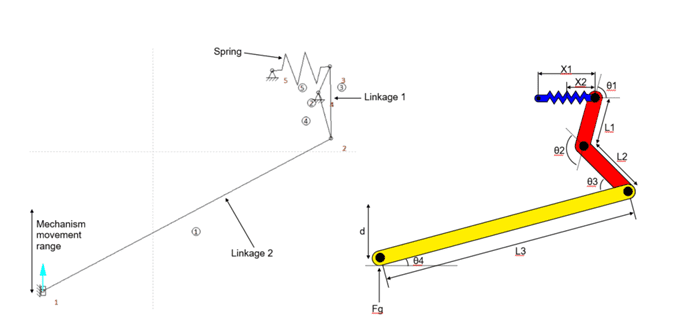

Summary:: I am making a landing gear mechanism, and am struggling to mathematically model it, the aim is to find the required properties for the spring for it to work.

Hi can you help me with a problem, I am making a landing gear mechanism and am struggling to model it mathematically. The aim is to find the required properties for the spring, for it to work. The approach is based on the conservation of energy, and the frictional losses are assumed to be zero.

k - spring constant

X1 – initial spring length

X2 – Final spring length

W – work done

d – travel distance

L1, L2, L3 – constant length

Θ2 – constant

Θ1, θ3, θ4 – variable

Fg – force due to gravity

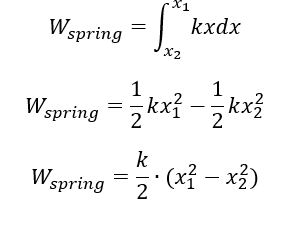

1 Finding work done by spring

Integrating Hooke’s law to express it in work done

2 Finding forces acting on the mechanism

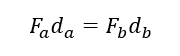

2.1 Calculating balanced moments

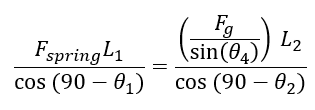

Since linkage 1 is balanced, the moments are equal to each other

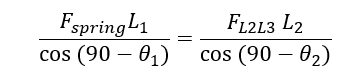

Adjusting for forces that aren’t acting tangential to the members of linkage 1.

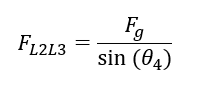

FL2L3 is the force acting linearly to the length of linkage 2

2.2 Adjusting for angled force

Finding relation between FL2L3 and Fg

Inserting the relation into the equation, we have

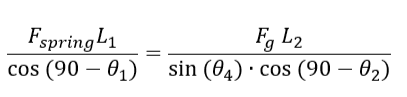

Rearranging

I don't know what to do from this point on, can you help with

1. Generally solving it?

2. How do you express all angles in terms of θ4?

Any help would be appreciated, thank you

Hi can you help me with a problem, I am making a landing gear mechanism and am struggling to model it mathematically. The aim is to find the required properties for the spring, for it to work. The approach is based on the conservation of energy, and the frictional losses are assumed to be zero.

k - spring constant

X1 – initial spring length

X2 – Final spring length

W – work done

d – travel distance

L1, L2, L3 – constant length

Θ2 – constant

Θ1, θ3, θ4 – variable

Fg – force due to gravity

1 Finding work done by spring

Integrating Hooke’s law to express it in work done

2 Finding forces acting on the mechanism

2.1 Calculating balanced moments

Since linkage 1 is balanced, the moments are equal to each other

Adjusting for forces that aren’t acting tangential to the members of linkage 1.

FL2L3 is the force acting linearly to the length of linkage 2

2.2 Adjusting for angled force

Finding relation between FL2L3 and Fg

Inserting the relation into the equation, we have

Rearranging

I don't know what to do from this point on, can you help with

1. Generally solving it?

2. How do you express all angles in terms of θ4?

Any help would be appreciated, thank you

Last edited: