- #1

PhysicsTest

- 238

- 26

- TL;DR Summary

- Require clarification of minimum voltage to motor windings

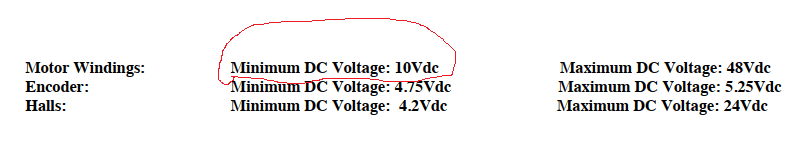

I have seen the following specifications in the Hurst motor data sheet.

i have confusion on the Minimum DC voltage to the motor windings. It says as 10Vdc, but even if i give less than 10V it should not damage the motor windings. I can understand the upper voltage if i cross it may damage the windings, but why minimum voltage? Please help.

i have confusion on the Minimum DC voltage to the motor windings. It says as 10Vdc, but even if i give less than 10V it should not damage the motor windings. I can understand the upper voltage if i cross it may damage the windings, but why minimum voltage? Please help.