- #1

robertjordan

- 71

- 0

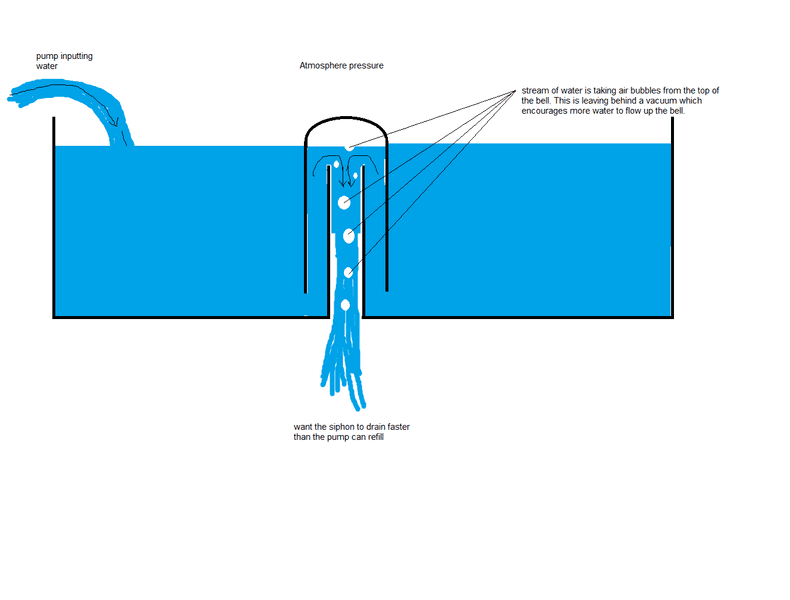

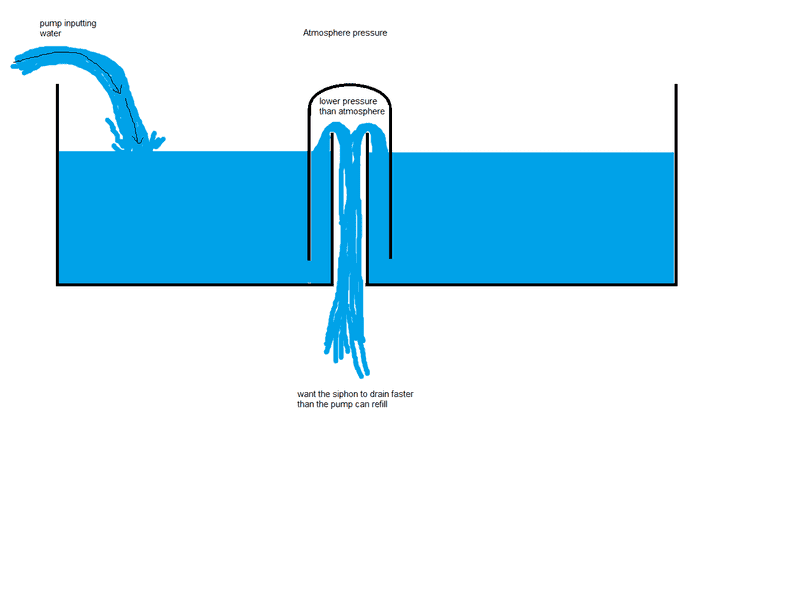

I'm trying to build a home aquaponics system, and a key component of the design I got off the internet is a bell siphon. So I'm trying to understand the physics of this siphon effect so I can optimize the weight and dimensions of the siphon to fit the size of my system.From what I read on the internet, the siphon works as follows:

- When the water first gets sucked down the vertical standpipe, it sucks some air down the tube and thus leaves a bit of a vacuum in the top of the bell. This will encourage more water to flow into the bell and down the tube.

- When the water level in the tank gets low enough, outside air is sucked into the bell and breaks that low pressure zone.

Is that correct?

Also, are there some equations I can use to see what effect changing the geometry of the siphon components will have? Higher elevation from tank bottom, larger ID on the bell, larger ID on the standpipe, taller bell, etc. Or even using some kind of tapered design?Thanks!

- When the water first gets sucked down the vertical standpipe, it sucks some air down the tube and thus leaves a bit of a vacuum in the top of the bell. This will encourage more water to flow into the bell and down the tube.

- When the water level in the tank gets low enough, outside air is sucked into the bell and breaks that low pressure zone.

Is that correct?

Also, are there some equations I can use to see what effect changing the geometry of the siphon components will have? Higher elevation from tank bottom, larger ID on the bell, larger ID on the standpipe, taller bell, etc. Or even using some kind of tapered design?Thanks!