- #1

omarmorocci

- 47

- 0

Hello everyone,

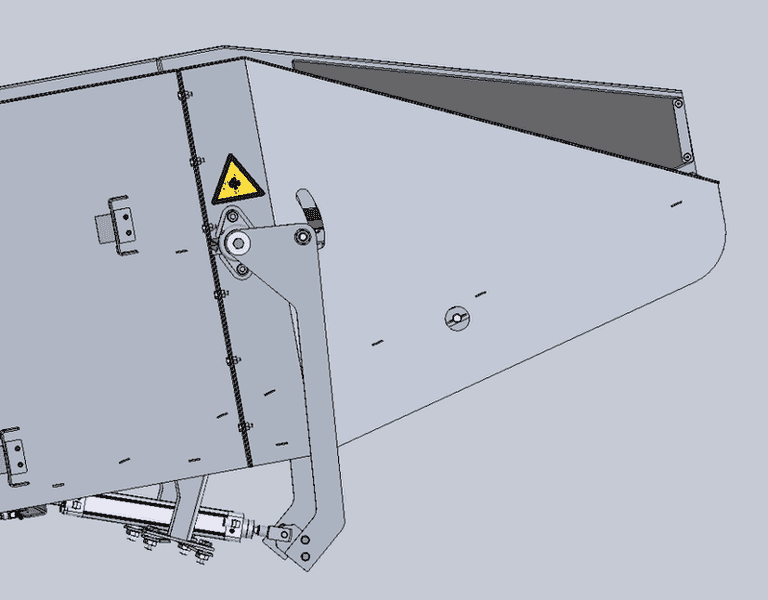

I am currently doing an internship and I am working on a part that opens and closes using a pneumatic cylinder as you can see bellow

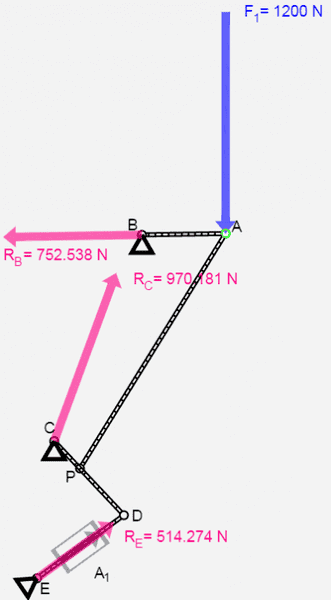

Here is a force diagram

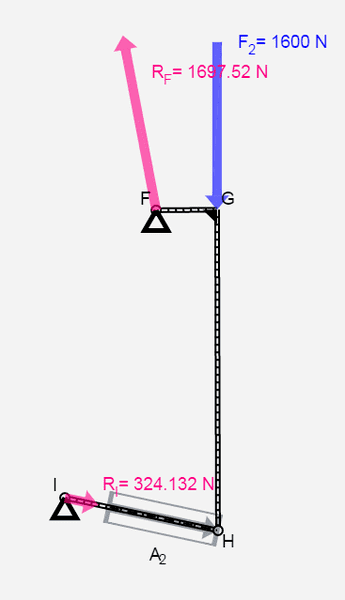

Here is a force diagram

I would like to redesign this in order to use a cylinder with a shorter stroke and perhaps a slightly bigger diameter .My current idea is to use a four bar linkage

I am open to new Ideas

I am currently doing an internship and I am working on a part that opens and closes using a pneumatic cylinder as you can see bellow

I would like to redesign this in order to use a cylinder with a shorter stroke and perhaps a slightly bigger diameter .My current idea is to use a four bar linkage

I am open to new Ideas