- #1

- 3,483

- 1,164

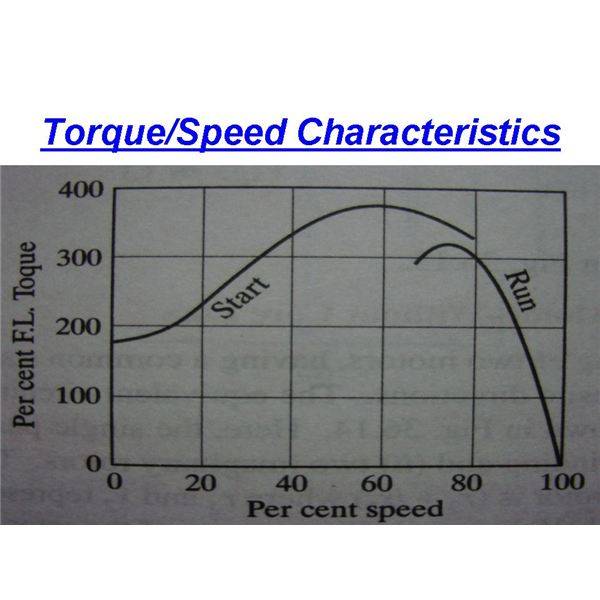

Single phase motor is not self starting, so it is started using some arrangement and the starting arrangement is disconnected(not always) once the motor is set in proper motion(about 70% of the maximum speed).

But I didn't understand this graph. From the starting moment, motor accelerates and catches speed. This must reduce the slip. So, the torque should go on decreasing as the speed goes up. Then why is the torque curve in the graph shown rising from the starting instant? Have I overlooked something?

But I didn't understand this graph. From the starting moment, motor accelerates and catches speed. This must reduce the slip. So, the torque should go on decreasing as the speed goes up. Then why is the torque curve in the graph shown rising from the starting instant? Have I overlooked something?