- #1

SevenToFive

- 56

- 3

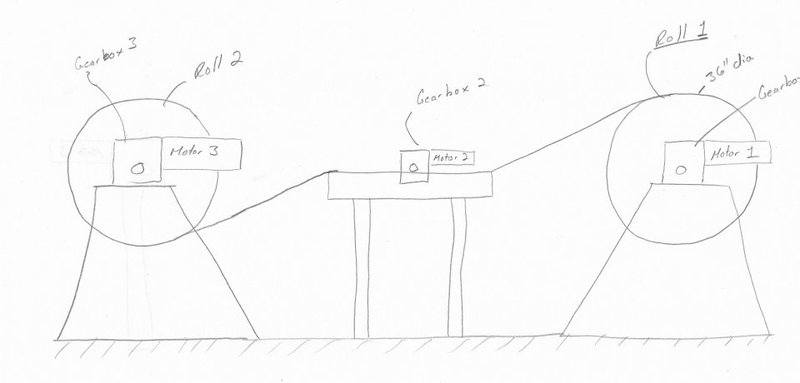

I have a system that will require 3 different gearboxes. Starting on the right we have a roll of felt that is 36 inches in diameter and weighs 4000lbs. The felt is going to be fed into the table in the middle off of roll number 1 on the right by gearbox number 2. Once the felt is cut, gearbox number 1 will pull the unused felt back onto roll 1. Gearbox number 3 on the left will pull the felt onto a new roll. These gearboxes will be powered by electric motors and using vfd's to control the speeds.

I am having a hard time trying to wrap my head around sizing these gearboxes since the original gearboxes offer much less torque that what is being calculated yet worked fine. We are replacing them since we are rebuilding the machine. At first I was going to calculate torque by taking the weight of the roll, 4000lbs and multiplying it by 18 inches which gives me 72000in-lbs or torque. However the gearboxes we took off of this machine are much smaller making only 5000in-lbs.

What am I missing here? Would gearbox number 2 require less torque since it is pulling the felt off of the top of the roll, and being assisted by gearbox number 1?

I am having a hard time trying to wrap my head around sizing these gearboxes since the original gearboxes offer much less torque that what is being calculated yet worked fine. We are replacing them since we are rebuilding the machine. At first I was going to calculate torque by taking the weight of the roll, 4000lbs and multiplying it by 18 inches which gives me 72000in-lbs or torque. However the gearboxes we took off of this machine are much smaller making only 5000in-lbs.

What am I missing here? Would gearbox number 2 require less torque since it is pulling the felt off of the top of the roll, and being assisted by gearbox number 1?