- #1

Noob of the Maths

- 52

- 6

Hello how are you :D

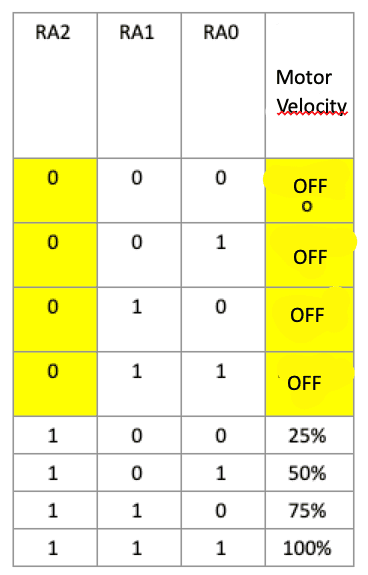

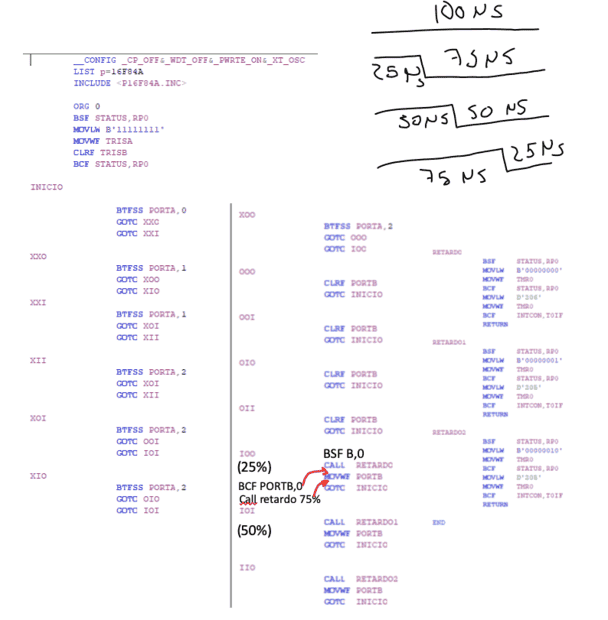

I have some problems with my code, which is to control the speed of a DC motor by pwm with the pic16f84A.

I already have the combinations and the diagram of the signals, but I still need to implement the part in bold.

How would the delays be implemented so that they have 25 us, 50 us, 75 us according to the diagram? I do not understand that part ;(

The time per cycle is 100 microseconds

I have some problems with my code, which is to control the speed of a DC motor by pwm with the pic16f84A.

I already have the combinations and the diagram of the signals, but I still need to implement the part in bold.

How would the delays be implemented so that they have 25 us, 50 us, 75 us according to the diagram? I do not understand that part ;(

The time per cycle is 100 microseconds