- #1

Dell

- 590

- 0

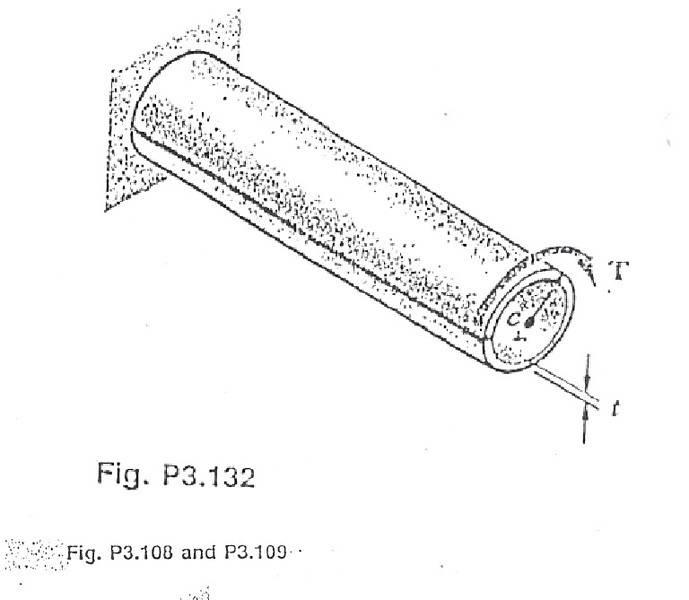

A thin- walled tube has been fabricated by bending a metal plate of thickness t into a cylinder of radius c and bending together the edges of the plate. Torque T is then applied to the tube, producing a shearing stress S1 and an angle twist P1 . Denoting by S2 and P1 , respectively, the shearing stress and the angle of twist which will develop if the bond suddenly fails, express the ratios S2/S1 and P2/P1 in term of the ratio c/t

all that i can see here is the obvious,

since it is a thin walled tube i can use the following

[tex]\tau[/tex]max=T*ravg/J

J=2pi*ravg3*t

dP/dt=T/(GJ)

now i know that ravg=c+t/2

what i also think is that at point 2, (P2,S2) i am at the critical point of the joint where it reaches its maximum so S2=[tex]\tau[/tex]max

but that's all i manage to get and nowehre near any kind of ratio c/t

all that i can see here is the obvious,

since it is a thin walled tube i can use the following

[tex]\tau[/tex]max=T*ravg/J

J=2pi*ravg3*t

dP/dt=T/(GJ)

now i know that ravg=c+t/2

what i also think is that at point 2, (P2,S2) i am at the critical point of the joint where it reaches its maximum so S2=[tex]\tau[/tex]max

but that's all i manage to get and nowehre near any kind of ratio c/t