- #1

Phg201

- 2

- 0

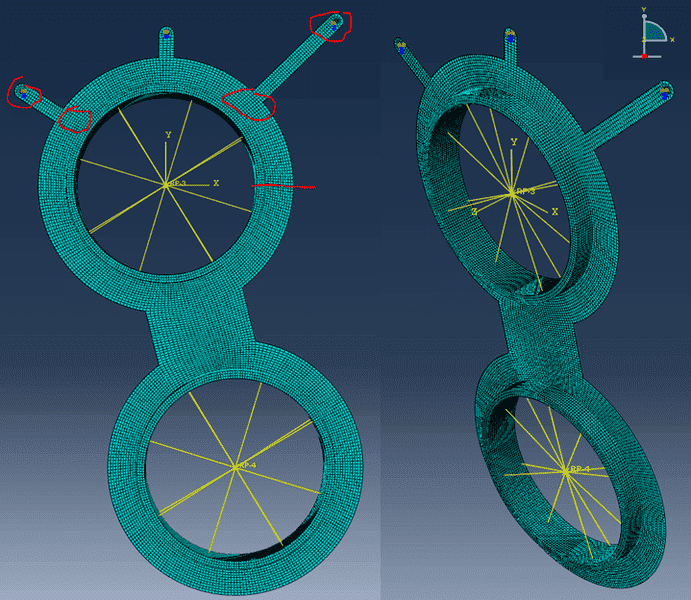

I have been given a structure to verify but I personally don't see a way of calculating the reactions & capacity of the parts without delving into a FEA analysis. I welcome any suggestions & help that you can give or insight, i am only trying to confirm the capacity & efficient sections & sizing is not absolutely critical.

The project involves a double pipe clamp, i am not concerned by the deformation of the pipe as it is large bore & suitably think no prevent any deflections. the proposed weight is estimated at a tonne per pipe. The construction method is a combination of bolting & welding. (Not shown in the pictures) Each pipe clamp is bolted to the top & bottom of the pipe & again additional plate is bolted to the centre connecting piece along the top & bottom pipe clamp flange. The section around the clamp is a tee-section, selected for stiffness with a bolted end joint at the connecting positions of the top & bottom pipe clamp sections. (These are horizontal along the x axis)

Tee-section prying will occur at the joint as 2 no. bolts will be situated either side of the t-section flange.

What might not be apparent from the images is that the pipe below is offset approximately 200mm along the y axis, from the top pipe.

The connecting plates along the top of the model (shows 3 offset plates, at varied angles) have changed from 3 to 2 plates at 60 degree angles from the horizontal (for simplicity). These are again bolted to the flange of the t-section & eye plates above.

The design is purely static & no dynamic loads are present & the tee-section construction method involves cutting plate to circumference & welding to the equivalent rolled plate in contact with the pipe. I have assumed that the pipe load occurs at the CoM.

diameter of pipe = 600mm (Fixed)

thickness all around = 10mm can be altered

All other dimensions can be altered to suit if required.

What I'm struggling to calculate at this stage is the reaction at the pipe clamp joint (crudely drawing Red line) & then the reactions at the connecting members (Crudely drawing red circles) but all recommendations are appreciated. This is the first time I've used a forum for a engineering question so please be kind, ha. Thanks in advance.

The project involves a double pipe clamp, i am not concerned by the deformation of the pipe as it is large bore & suitably think no prevent any deflections. the proposed weight is estimated at a tonne per pipe. The construction method is a combination of bolting & welding. (Not shown in the pictures) Each pipe clamp is bolted to the top & bottom of the pipe & again additional plate is bolted to the centre connecting piece along the top & bottom pipe clamp flange. The section around the clamp is a tee-section, selected for stiffness with a bolted end joint at the connecting positions of the top & bottom pipe clamp sections. (These are horizontal along the x axis)

Tee-section prying will occur at the joint as 2 no. bolts will be situated either side of the t-section flange.

What might not be apparent from the images is that the pipe below is offset approximately 200mm along the y axis, from the top pipe.

The connecting plates along the top of the model (shows 3 offset plates, at varied angles) have changed from 3 to 2 plates at 60 degree angles from the horizontal (for simplicity). These are again bolted to the flange of the t-section & eye plates above.

The design is purely static & no dynamic loads are present & the tee-section construction method involves cutting plate to circumference & welding to the equivalent rolled plate in contact with the pipe. I have assumed that the pipe load occurs at the CoM.

diameter of pipe = 600mm (Fixed)

thickness all around = 10mm can be altered

All other dimensions can be altered to suit if required.

What I'm struggling to calculate at this stage is the reaction at the pipe clamp joint (crudely drawing Red line) & then the reactions at the connecting members (Crudely drawing red circles) but all recommendations are appreciated. This is the first time I've used a forum for a engineering question so please be kind, ha. Thanks in advance.