- #1

saltine

- 89

- 0

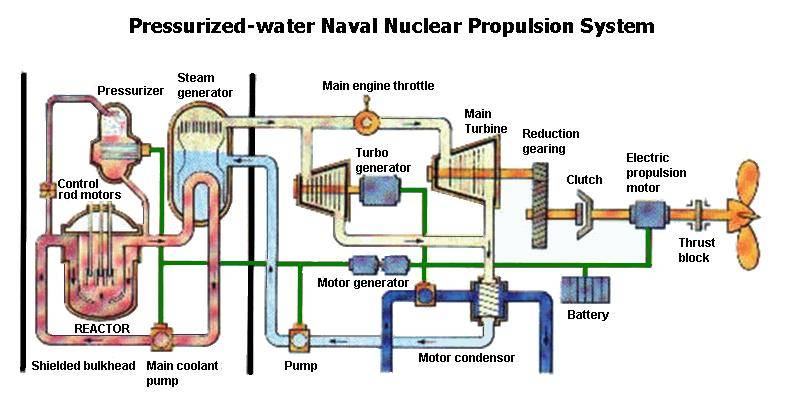

Hi, I was looking at the following diagram and have some questions:

Is the purpose of the pumps to transport liquid of one temperature to another section of the loop?

Is it more efficient to use steam to turn turbine or to use water to turn a turbine? (Is hydroelectric more efficient, but given that the energy output of nuclear reaction is in the form of heat, which can make steam, therefore steam turbine is used?)

What is the function of the Pressurizer? Is it for measuring the pressure to control the control rods and the coolant pump?

- Thanks

Is the purpose of the pumps to transport liquid of one temperature to another section of the loop?

Is it more efficient to use steam to turn turbine or to use water to turn a turbine? (Is hydroelectric more efficient, but given that the energy output of nuclear reaction is in the form of heat, which can make steam, therefore steam turbine is used?)

What is the function of the Pressurizer? Is it for measuring the pressure to control the control rods and the coolant pump?

- Thanks