- #1

fede280385

- 2

- 1

- TL;DR Summary

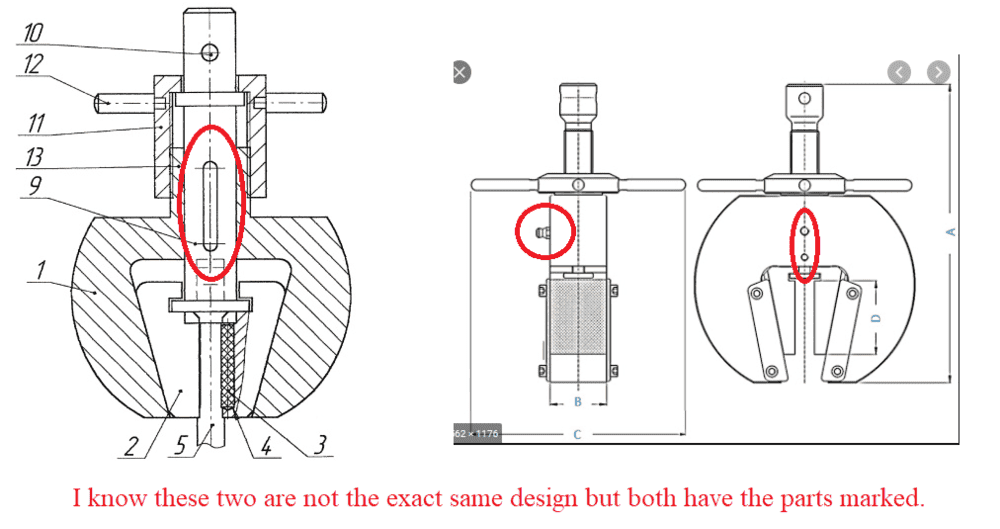

- Desing of wedge tensile grip

Hello to all.

I am new at PF. I am very happy to be here now that I know you.

I am at the middle of a UTM (universal tensile machine) design. My machine is going to be a simple testing machine in which I only intent to measure the ultimate tensile strenght. That been said, I want to be as clear as I can be.

Part of the design includes the fabrication of the wedge tensile grips (or tensile clamp body). I have selected one design and it is the one with moving body and stationary jaws (you can see the attached pictures).

I need to know to continue with the design what is tha part marked in red and what is it used for, because I can not understand it.

Thank you all.

Hope you reply soon

I am new at PF. I am very happy to be here now that I know you.

I am at the middle of a UTM (universal tensile machine) design. My machine is going to be a simple testing machine in which I only intent to measure the ultimate tensile strenght. That been said, I want to be as clear as I can be.

Part of the design includes the fabrication of the wedge tensile grips (or tensile clamp body). I have selected one design and it is the one with moving body and stationary jaws (you can see the attached pictures).

I need to know to continue with the design what is tha part marked in red and what is it used for, because I can not understand it.

Thank you all.

Hope you reply soon