- #1

mechengstudent

- 18

- 0

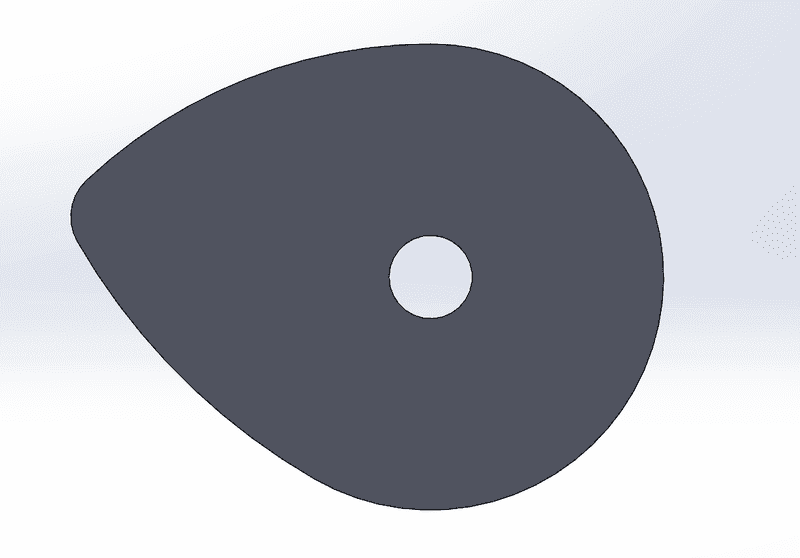

I am trying to determine what type of cam this is from the various cam diagrams but they don't really help as they all seem very similar. I have a simple four arc cam, so a base circle/arc, a nose circle/arc and an arc on one side tangent to the nose and base arcs, and another of slightly different radius on the other side/flank.

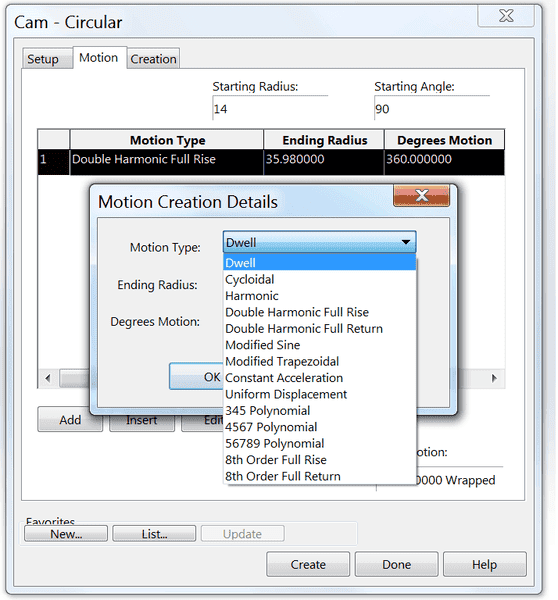

I am trying to design this in Solidworks but they have a drop down list containing a whole heap of different cams like so:

Can someone tell me what type of cam/motion of the cam this is?

I am trying to design this in Solidworks but they have a drop down list containing a whole heap of different cams like so:

Can someone tell me what type of cam/motion of the cam this is?