- #1

Petes

- 10

- 0

- TL;DR Summary

- How do you guys find the gears you need?

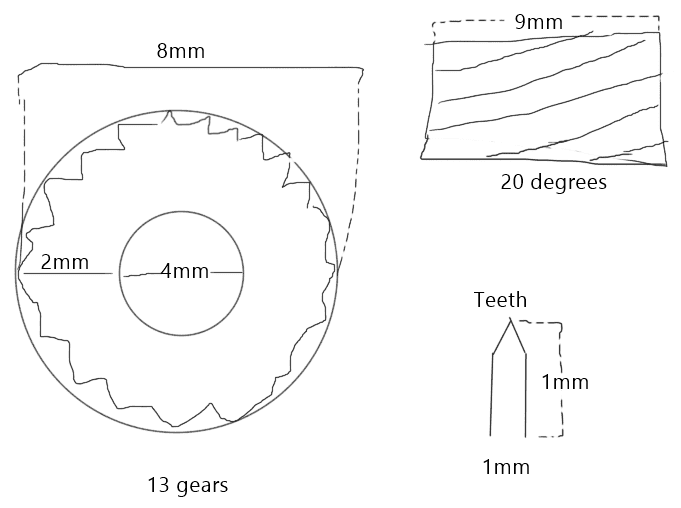

So I have a broken plastic pinion gear that belongs to my microscope and I'm wondering if there are standard sizes or how am I supposed to get a replacement? How do you guys find the gears you need? Seems like a pretty hard thing to find online.

It's an helical pinion gear. I have the dimensions but it's a small piece and I don't know if it's possible to 3D print something like that.

Just in case here are the dimensions, sorry for the bad quality drawing:

It's an helical pinion gear. I have the dimensions but it's a small piece and I don't know if it's possible to 3D print something like that.

Just in case here are the dimensions, sorry for the bad quality drawing:

Attachments

Last edited: