- #1

bigfish2000

- 4

- 0

Hello,

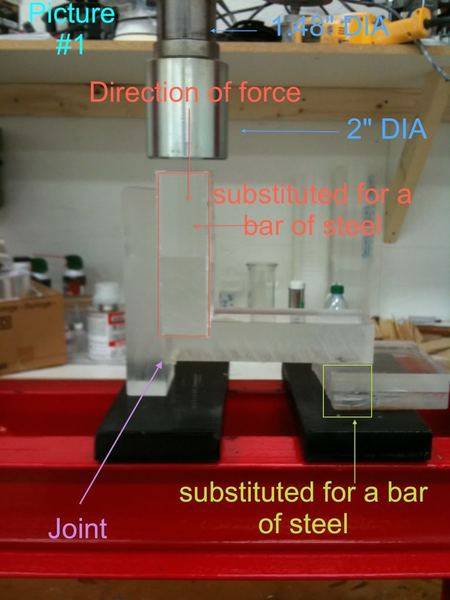

I am using a hydraulic shop press, to test the strength of acrylic weld joints.

Here are my questions.

-I replaced the pressure gauge that was included with a very precise digital gauge. The hydraulic piston that presses down has a removable circular head 2” DIA. Its neck is 1.48” in DIA. Thus the piston head is roughly 3.14 square inches and the neck has a 1.719 square inch surface area. If my pressure gauge reads 1000 Psi, how many LBS of force are being applied to my work area?

Would be 3140 LBS of force or 1719 LBS?

-My second question is a little more complicated. It involves the design set up of the experiment.

I have made 50 samples identical to the one shown in the pictures. I want to test shear strength with the samples.

(See picture #1).

My thoughts are this; using a bar of steel to distribute the pressure evenly across the joint I would apply force with my press (red arrow). The sample will naturally want to tip as pressure is applied. In order to prevent the sample from tipping I would keep the opposing side supported with a bar of steel (green box). By supporting the opposing end (green box) will this affect the accuracy of my test results? Would it make the results artificially higher?

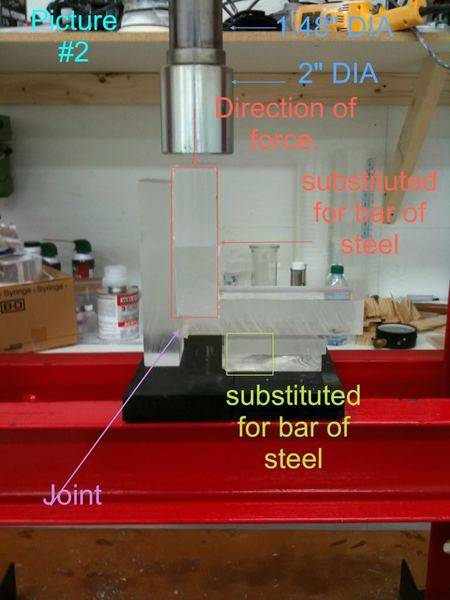

Acrylic flexes even over a short distance. Flexing will act as a lever and fulcrum correct? Should I move my support bar in further towards the (red arrow) to prevent flexing? (See picture #2) Or will this affect the results of the experiment?

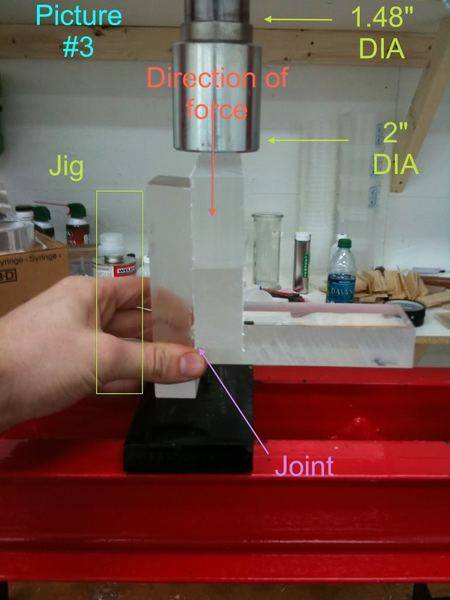

(See picture #3)

Should I have the samples held from the backside in this manner using a steel jig?

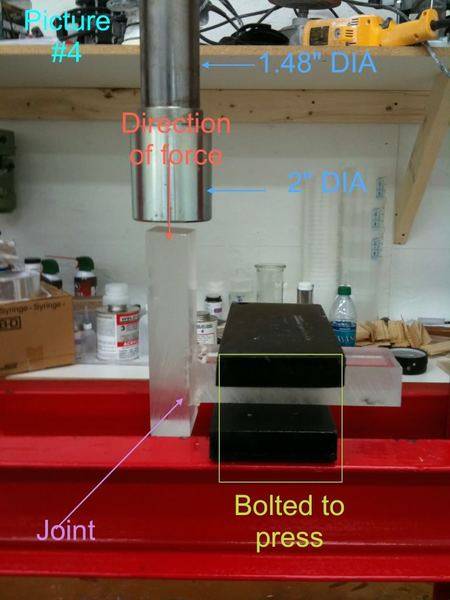

(See Picture #4)

Or should I have the samples held like this?

-When applying force to the test samples I am using a bar of steel to distribute the weight across the joint evenly. How do I translate the gauge PSI reading into how much force is being applied to the joint? And how do I calculate how many PSI at which the joint broke at?

For instance my pressure gauge reads 1000 PSI. There for the piston should be exerting 3140 LBS or 1719 LBS of force. Would I determine this by dividing 3140 LBS or 1719 LBS of force by the total surface area of the joint (2x1”=2 sqin). Thus 1570 PSI or 859.5 PSI of force was being applied to the joint?

Or would the steel bar affect PSI being applied? Picture #1

Picture #2

Picture #3

Picture #4

I am using a hydraulic shop press, to test the strength of acrylic weld joints.

Here are my questions.

-I replaced the pressure gauge that was included with a very precise digital gauge. The hydraulic piston that presses down has a removable circular head 2” DIA. Its neck is 1.48” in DIA. Thus the piston head is roughly 3.14 square inches and the neck has a 1.719 square inch surface area. If my pressure gauge reads 1000 Psi, how many LBS of force are being applied to my work area?

Would be 3140 LBS of force or 1719 LBS?

-My second question is a little more complicated. It involves the design set up of the experiment.

I have made 50 samples identical to the one shown in the pictures. I want to test shear strength with the samples.

(See picture #1).

My thoughts are this; using a bar of steel to distribute the pressure evenly across the joint I would apply force with my press (red arrow). The sample will naturally want to tip as pressure is applied. In order to prevent the sample from tipping I would keep the opposing side supported with a bar of steel (green box). By supporting the opposing end (green box) will this affect the accuracy of my test results? Would it make the results artificially higher?

Acrylic flexes even over a short distance. Flexing will act as a lever and fulcrum correct? Should I move my support bar in further towards the (red arrow) to prevent flexing? (See picture #2) Or will this affect the results of the experiment?

(See picture #3)

Should I have the samples held from the backside in this manner using a steel jig?

(See Picture #4)

Or should I have the samples held like this?

-When applying force to the test samples I am using a bar of steel to distribute the weight across the joint evenly. How do I translate the gauge PSI reading into how much force is being applied to the joint? And how do I calculate how many PSI at which the joint broke at?

For instance my pressure gauge reads 1000 PSI. There for the piston should be exerting 3140 LBS or 1719 LBS of force. Would I determine this by dividing 3140 LBS or 1719 LBS of force by the total surface area of the joint (2x1”=2 sqin). Thus 1570 PSI or 859.5 PSI of force was being applied to the joint?

Or would the steel bar affect PSI being applied? Picture #1

Picture #2

Picture #3

Picture #4

Last edited: