willmac8

- 6

- 1

Hi all,

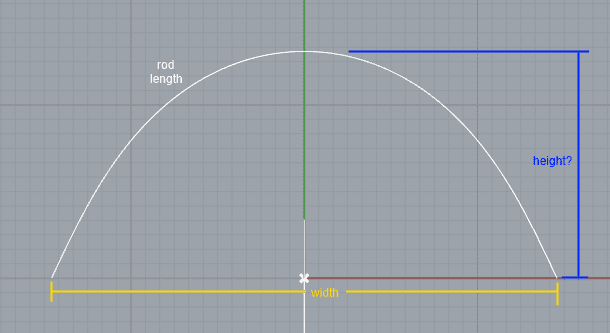

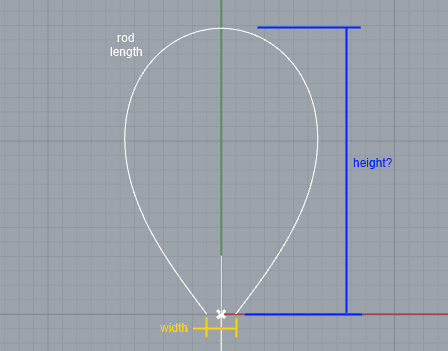

I'm trying to do something that might be impossible, but seems to me should have a solution: Finding the height (or displacement) of a long, thin rod or wire under horizontal compression forces at the ends (pinned, not clamped) causing it to bend into a stable arch-like shape given only the length of the rod, the distance between the pinned ends ("width" in the images, always < length. imagine a rope being tied between the endpoints holding the arch in a stable shape), and possibly the parameters unique to the rod's material & cross-section (Young’s modulus, E, and the area moment of inertia, I). Ideally, I'd like to find a way to describe parametrically the shape the rod makes, from which I could easily find the max height (displacement). I have yet to find a formula for this though. The closest I've come to finding a solution is these resources:

http://www.scielo.org.mx/pdf/rmfe/v53n2/v53n2a8.pdf (Figure 1 on pg 189 is exactly what I'm trying to find a formula to describe)

http://www.princeton.edu/mae/people/faculty/faccvroyce/homepage/publications/DomHRoy-JNLS97.pdf

http://solidmechanics.org/Text/Chapter10_4/Chapter10_4.php

http://levien.com/phd/elastica_hist.pdf

http://thegeometryofbending.blogspot.com/

I unfortunately don't understand Euler's work well enough to derive this on my own. I've seen references to the "Jacobi elliptic functions" and "complete elliptic integral of the first (or second) kind", but don't understand how to find solutions for those either.

Also, if it's a matter of finding a solution numerically, that would work great as I'm trying to write an algorithm (in C or python) to solve this anyway. I would ideally take any 2 of the 3 parameters (length, height, and width between the endpoints) and output the unknown variable and a formula for the shape of the curve.

Thanks for any help or insight you can provide!

I'm trying to do something that might be impossible, but seems to me should have a solution: Finding the height (or displacement) of a long, thin rod or wire under horizontal compression forces at the ends (pinned, not clamped) causing it to bend into a stable arch-like shape given only the length of the rod, the distance between the pinned ends ("width" in the images, always < length. imagine a rope being tied between the endpoints holding the arch in a stable shape), and possibly the parameters unique to the rod's material & cross-section (Young’s modulus, E, and the area moment of inertia, I). Ideally, I'd like to find a way to describe parametrically the shape the rod makes, from which I could easily find the max height (displacement). I have yet to find a formula for this though. The closest I've come to finding a solution is these resources:

http://www.scielo.org.mx/pdf/rmfe/v53n2/v53n2a8.pdf (Figure 1 on pg 189 is exactly what I'm trying to find a formula to describe)

http://www.princeton.edu/mae/people/faculty/faccvroyce/homepage/publications/DomHRoy-JNLS97.pdf

http://solidmechanics.org/Text/Chapter10_4/Chapter10_4.php

http://levien.com/phd/elastica_hist.pdf

http://thegeometryofbending.blogspot.com/

I unfortunately don't understand Euler's work well enough to derive this on my own. I've seen references to the "Jacobi elliptic functions" and "complete elliptic integral of the first (or second) kind", but don't understand how to find solutions for those either.

Also, if it's a matter of finding a solution numerically, that would work great as I'm trying to write an algorithm (in C or python) to solve this anyway. I would ideally take any 2 of the 3 parameters (length, height, and width between the endpoints) and output the unknown variable and a formula for the shape of the curve.

Thanks for any help or insight you can provide!