Jarfi

- 384

- 12

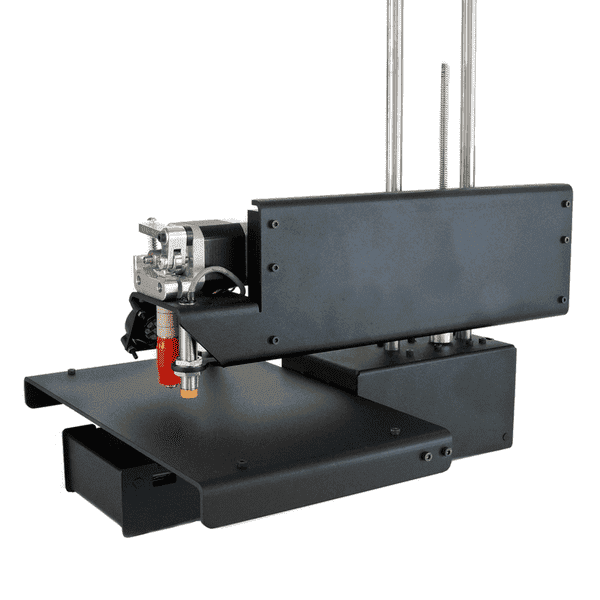

I was thinking of buying this: http://printrbot.com/shop/simple-metal-kit/

I have never used or bought a 3d printer, but I don't feel like going for a prototyping station with all my CAD models to constantly print small parts, so before jumping in the deep pool I'd like to ask some questions for people who know more than me about 3d printing.

Is arduino, general engineering and handyman knowledge enough to assemble this by oneself?

Will this quality of print and PLA material be able to print working 20mm pitch diameter gears, and gear racks of similar sizes for prototyping?

Is this sort of 3d printer meant for engineering and prototyping or would Is this just something to create statues and gimmicks?

Should I wait a few months of after xmas for the price do drop or is it lowest at his point?

Since I'm already paying 540$ should I just go all the way and buy the heated platform one?

Am I making the right choice with a 3d printer for beginners or are there more professional/sturdy printers out there in a similar price range?

Sorry if I am being off topic and thanks in advance!

-Gabriel

- Model: 1403

- Build Volume: 6″ x 6″ x 6″ / 150mm x 150mm x 150mm / 216 cubic inches

- Print Resolution: 100 Microns

- Print Speed: 80mm/sec max recommended

- Filament: 1.75mm PLA (sample included)

I have never used or bought a 3d printer, but I don't feel like going for a prototyping station with all my CAD models to constantly print small parts, so before jumping in the deep pool I'd like to ask some questions for people who know more than me about 3d printing.

Is arduino, general engineering and handyman knowledge enough to assemble this by oneself?

Will this quality of print and PLA material be able to print working 20mm pitch diameter gears, and gear racks of similar sizes for prototyping?

Is this sort of 3d printer meant for engineering and prototyping or would Is this just something to create statues and gimmicks?

Should I wait a few months of after xmas for the price do drop or is it lowest at his point?

Since I'm already paying 540$ should I just go all the way and buy the heated platform one?

Am I making the right choice with a 3d printer for beginners or are there more professional/sturdy printers out there in a similar price range?

Sorry if I am being off topic and thanks in advance!

-Gabriel

Last edited by a moderator: