SUMMARY

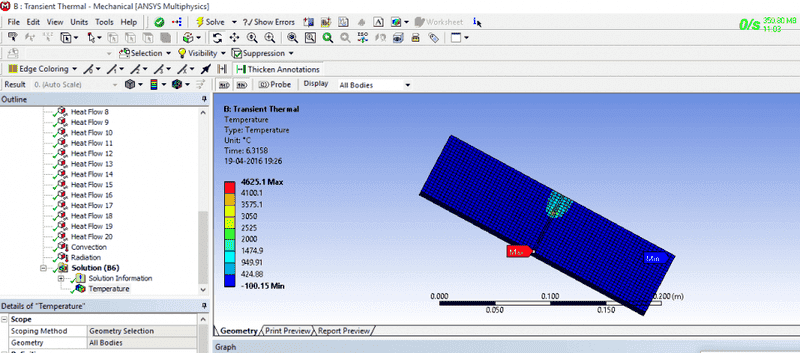

The discussion focuses on performing a transient thermal analysis of a butt welded joint using ANSYS. The user applied a heat flow of 3200 watts, with boundary conditions for convection (coefficient of 11.14) and radiation (emissivity of 0.4), but encountered a minimum temperature of -132.52°C, which is unexpected. Troubleshooting steps suggested include disabling boundary conditions, checking for nonlinear material properties, and remeshing the geometry. The user is also exploring the possibility of implementing a cooling cycle in ANSYS Workbench.

PREREQUISITES

- Understanding of ANSYS Workbench for thermal analysis

- Knowledge of transient thermal analysis principles

- Familiarity with boundary conditions in thermal simulations

- Experience with nonlinear material properties in thermal modeling

NEXT STEPS

- Learn how to implement cooling cycles in ANSYS Workbench

- Research techniques for remeshing in ANSYS to improve simulation accuracy

- Explore the effects of nonlinear material properties on thermal analysis results

- Study the impact of boundary conditions on transient thermal simulations

USEFUL FOR

Engineers and analysts involved in thermal simulations, particularly those working with welding processes and transient thermal analysis in ANSYS.