an1mal_69

- 4

- 0

Moderator's note: thread moved from Homework Help forums to Mechanical Engineering forum. Welcome to PF an1mal_69

Apologies, this is not homework, but a real world problem.

Front suspension system, consisting of 2 wishbones supporting a wheel hub via (x2) ball joints at the top and bottom. Other connections are apparent, for steering etc, but not relevant in this instance. The ball joints are secured to the arms with 4 bolts.

The proposal is to template the top ball joint and insert a spacer of around 30mm between the arm and ball joint using extended and uprated fasteners.

I had intended to make the spacer from Acetal Nylon having compressional properties equal to or greater than Aluminum. Certain individuals have questioned the material citing the spacer will be subject to shear stress, I argued the fasteners would be taking the shear loads.?

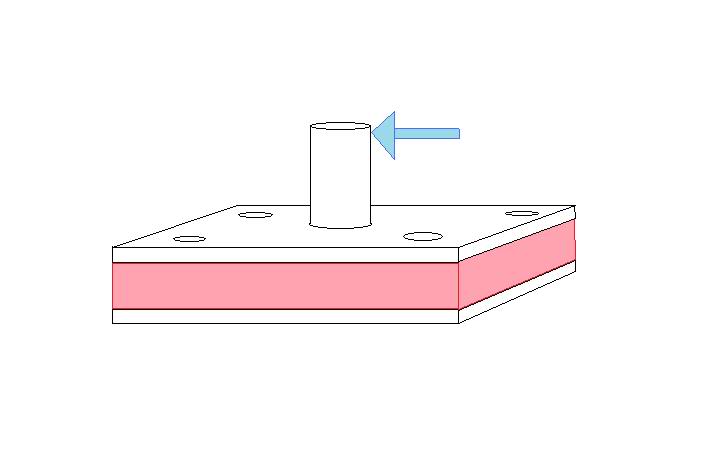

If you take the rough diagram into consideration..assume the bottom plate as fixed, and there are (x4) fasteners clamping the spacer in place. If a force is applied to the bar on the upper plate (in any direction) what are the effects/loads on the spacer.?

Many thanks in advance, Nik..

Apologies, this is not homework, but a real world problem.

Homework Statement

Front suspension system, consisting of 2 wishbones supporting a wheel hub via (x2) ball joints at the top and bottom. Other connections are apparent, for steering etc, but not relevant in this instance. The ball joints are secured to the arms with 4 bolts.

The proposal is to template the top ball joint and insert a spacer of around 30mm between the arm and ball joint using extended and uprated fasteners.

I had intended to make the spacer from Acetal Nylon having compressional properties equal to or greater than Aluminum. Certain individuals have questioned the material citing the spacer will be subject to shear stress, I argued the fasteners would be taking the shear loads.?

If you take the rough diagram into consideration..assume the bottom plate as fixed, and there are (x4) fasteners clamping the spacer in place. If a force is applied to the bar on the upper plate (in any direction) what are the effects/loads on the spacer.?

Many thanks in advance, Nik..

Last edited by a moderator: