skrat

- 740

- 8

- TL;DR

- According to Zienkiewicz, the body forces in static equilibrium should equal zero, but in my simulations they don't.

Hi,

I have an issue with understanding the body forces in the context of FEM simulations. I am using freefem to do the simulations.

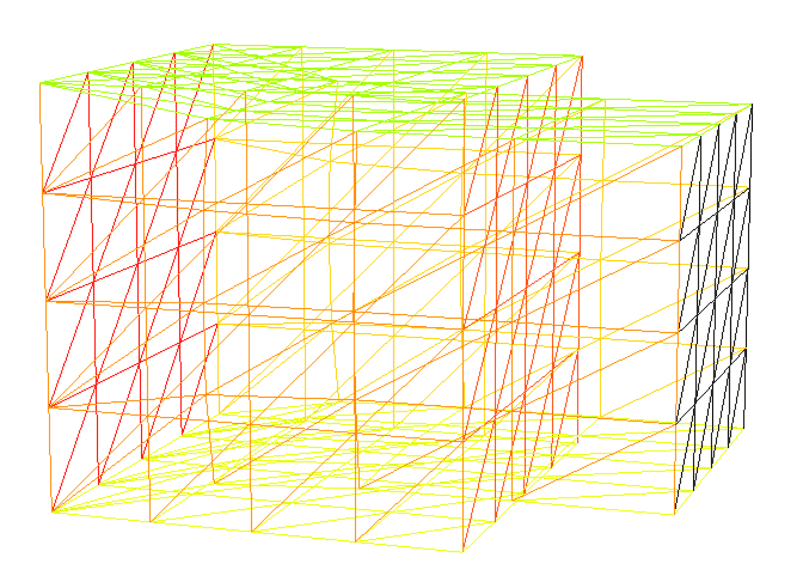

So I took a simple unit cube, fixed the displacements at side ##x=0## and prescribed a displacement ##u_x = 0.025## at ##x=1##. If required, the entire script is given below.

[CODE title="Cube example"]load "medit"

include "cube.idp"

int[int] numberOfNodes = [4, 4, 4]; // Nodes per side.

real [int, int] boundaryRange = [[0.0, 1.0], [0.0, 1.0], [0.0, 1.0]]; // Side lengths.

int [int, int] labels = [[1, 2], [3, 4], [5, 6]]; // Labels.

mesh3 Th = Cube(numberOfNodes, boundaryRange, labels);

real E = 2230e6;

real sigma = 0.4;

real mu = E/(2*(1+sigma));

real lambda = E*sigma/((1+sigma)*(1-2*sigma));

fespace Vh(Th,P2);

Vh u1,u2,u3, v1,v2,v3;

real sqrt2=sqrt(2.);

macro epsilon(u1,u2,u3) [dx(u1),dy(u2),dz(u3),(dz(u2)+dy(u3))/sqrt2,(dz(u1)+dx(u3))/sqrt2,(dy(u1)+dx(u2))/sqrt2] // EOM

macro div(u1,u2,u3) ( dx(u1)+dy(u2)+dz(u3) ) // EOM

solve Lame([u1,u2,u3],[v1,v2,v3])=

int3d(Th)(

lambda*div(u1,u2,u3)*div(v1,v2,v3)

+2.*mu*( epsilon(u1,u2,u3)'*epsilon(v1,v2,v3) ) //')

)

// - int3d(Th) (gravity*v3)

+ on(1,u1=0,u2=0,u3=0)

+ on(2,u1=0.025)

;

real dmax = u3[].max;

count << " max deplacement = " << dmax << endl;

real coef= 0.1/dmax;

int[int] ref2=[1,0,2,0];

mesh3 Thm=movemesh3(Th,transfo=[x+u1*coef,y+u2*coef,z+u3*coef],label=ref2);

Thm=change(Thm,label=ref2);

plot(Th,Thm, wait=1,cmm="coef amplification = "+coef );[/CODE]

Now the results look completely fine to me:

However, the problem.

The problems start when I try to compute the body forces. Now, according to O.C. Zienkiewicz, ... J.Z. Zhu, in The Finite Element Method: its Basis and Fundamentals (Seventh Edition), 2013 (snapshot of a chapter given here) for any element in the static equilibrium we can write

$$\nabla \cdot \sigma + b = 0$$

where ##\sigma## is the stress tensor and ##b## is a vector of body forces.

Now in my case, there are no external body forces (e.g. gravity), so ##b=0## which in turn means ##\nabla \cdot \sigma = 0##.

So I computed the divergence of the stress tensor, where the divergence of a tensor ##T## is defined as

$$ (\nabla \cdot T)_i = \frac{\partial T_{ij}}{\partial x_j} $$

assuming the Einstein summation rule.

Here is my script:

[CODE title="Stress divergence computation."]// UPDATE

macro getTensorDivX(sxx, syy, szz, syz, sxz, sxy) (dx(sxx) + dy(sxy) + dz(sxz)) // EOM

macro getTensorDivY(sxx, syy, szz, syz, sxz, sxy) (dx(sxy) + dy(syy) + dz(syz)) // EOM

macro getTensorDivZ(sxx, syy, szz, syz, sxz, sxy) (dx(sxz) + dy(syz) + dz(szz)) // EOM

macro sigma(u1, u2, u3) [(lambda + 2 * mu) * dx(u1) + lambda * dy(u2) + lambda * dz(u3),

lambda * dx(u1) + (lambda + 2 * mu) * dy(u2) + lambda * dz(u3),

lambda + dx(u1) + lambda * dy(u2) + (lambda + 2 * mu) * dz(u3),

2 * mu * (dz(u2)+dy(u3)),

2 * mu * (dz(u1)+dx(u3)),

2 * mu * (dy(u1)+dx(u2))] // EOM

fespace Nh(Th, P1);

Nh sxx, syy, szz, syz, sxz, sxy;

Nh rx, ry, rz, r;

// Compute stresses.

sxx = sigma(u1, u2, u3)[0];

syy = sigma(u1, u2, u3)[1];

szz = sigma(u1, u2, u3)[2];

syz = sigma(u1, u2, u3)[3];

sxz = sigma(u1, u2, u3)[4];

sxy = sigma(u1, u2, u3)[5];

// Compute residuums.

rx = getTensorDivX(sxx, syy, szz, syz, sxz, sxy);

ry = getTensorDivY(sxx, syy, szz, syz, sxz, sxy);

rz = getTensorDivZ(sxx, syy, szz, syz, sxz, sxy);

for (int i = 0; i < r.n; i++) {

r[] = dist(rx[], ry[], rz[]);

}

count << "Average body force (stress divergence) = " << r[].sum / r.n << endl;[/CODE]

But I was extremely surprised to find out that the average norm of body forces is of order ##10^7##, which is not even close to 0.

Question

I have two questions.

1. I am not expecting that any of you is familiar with the FreeFem++. If you are, even better, you can help me understand what I am doing wrong in my script.

2. Am I making wrong assumptions? Should I not be surprised that the divergence of the stress tensor is not zero? Is this not even a problem but rather an expected result? If yes, could you help me understand why?

I have an issue with understanding the body forces in the context of FEM simulations. I am using freefem to do the simulations.

So I took a simple unit cube, fixed the displacements at side ##x=0## and prescribed a displacement ##u_x = 0.025## at ##x=1##. If required, the entire script is given below.

[CODE title="Cube example"]load "medit"

include "cube.idp"

int[int] numberOfNodes = [4, 4, 4]; // Nodes per side.

real [int, int] boundaryRange = [[0.0, 1.0], [0.0, 1.0], [0.0, 1.0]]; // Side lengths.

int [int, int] labels = [[1, 2], [3, 4], [5, 6]]; // Labels.

mesh3 Th = Cube(numberOfNodes, boundaryRange, labels);

real E = 2230e6;

real sigma = 0.4;

real mu = E/(2*(1+sigma));

real lambda = E*sigma/((1+sigma)*(1-2*sigma));

fespace Vh(Th,P2);

Vh u1,u2,u3, v1,v2,v3;

real sqrt2=sqrt(2.);

macro epsilon(u1,u2,u3) [dx(u1),dy(u2),dz(u3),(dz(u2)+dy(u3))/sqrt2,(dz(u1)+dx(u3))/sqrt2,(dy(u1)+dx(u2))/sqrt2] // EOM

macro div(u1,u2,u3) ( dx(u1)+dy(u2)+dz(u3) ) // EOM

solve Lame([u1,u2,u3],[v1,v2,v3])=

int3d(Th)(

lambda*div(u1,u2,u3)*div(v1,v2,v3)

+2.*mu*( epsilon(u1,u2,u3)'*epsilon(v1,v2,v3) ) //')

)

// - int3d(Th) (gravity*v3)

+ on(1,u1=0,u2=0,u3=0)

+ on(2,u1=0.025)

;

real dmax = u3[].max;

count << " max deplacement = " << dmax << endl;

real coef= 0.1/dmax;

int[int] ref2=[1,0,2,0];

mesh3 Thm=movemesh3(Th,transfo=[x+u1*coef,y+u2*coef,z+u3*coef],label=ref2);

Thm=change(Thm,label=ref2);

plot(Th,Thm, wait=1,cmm="coef amplification = "+coef );[/CODE]

Now the results look completely fine to me:

However, the problem.

The problems start when I try to compute the body forces. Now, according to O.C. Zienkiewicz, ... J.Z. Zhu, in The Finite Element Method: its Basis and Fundamentals (Seventh Edition), 2013 (snapshot of a chapter given here) for any element in the static equilibrium we can write

$$\nabla \cdot \sigma + b = 0$$

where ##\sigma## is the stress tensor and ##b## is a vector of body forces.

Now in my case, there are no external body forces (e.g. gravity), so ##b=0## which in turn means ##\nabla \cdot \sigma = 0##.

So I computed the divergence of the stress tensor, where the divergence of a tensor ##T## is defined as

$$ (\nabla \cdot T)_i = \frac{\partial T_{ij}}{\partial x_j} $$

assuming the Einstein summation rule.

Here is my script:

[CODE title="Stress divergence computation."]// UPDATE

macro getTensorDivX(sxx, syy, szz, syz, sxz, sxy) (dx(sxx) + dy(sxy) + dz(sxz)) // EOM

macro getTensorDivY(sxx, syy, szz, syz, sxz, sxy) (dx(sxy) + dy(syy) + dz(syz)) // EOM

macro getTensorDivZ(sxx, syy, szz, syz, sxz, sxy) (dx(sxz) + dy(syz) + dz(szz)) // EOM

macro sigma(u1, u2, u3) [(lambda + 2 * mu) * dx(u1) + lambda * dy(u2) + lambda * dz(u3),

lambda * dx(u1) + (lambda + 2 * mu) * dy(u2) + lambda * dz(u3),

lambda + dx(u1) + lambda * dy(u2) + (lambda + 2 * mu) * dz(u3),

2 * mu * (dz(u2)+dy(u3)),

2 * mu * (dz(u1)+dx(u3)),

2 * mu * (dy(u1)+dx(u2))] // EOM

fespace Nh(Th, P1);

Nh sxx, syy, szz, syz, sxz, sxy;

Nh rx, ry, rz, r;

// Compute stresses.

sxx = sigma(u1, u2, u3)[0];

syy = sigma(u1, u2, u3)[1];

szz = sigma(u1, u2, u3)[2];

syz = sigma(u1, u2, u3)[3];

sxz = sigma(u1, u2, u3)[4];

sxy = sigma(u1, u2, u3)[5];

// Compute residuums.

rx = getTensorDivX(sxx, syy, szz, syz, sxz, sxy);

ry = getTensorDivY(sxx, syy, szz, syz, sxz, sxy);

rz = getTensorDivZ(sxx, syy, szz, syz, sxz, sxy);

for (int i = 0; i < r.n; i++) {

r[] = dist(rx[], ry[], rz[]);

}

count << "Average body force (stress divergence) = " << r[].sum / r.n << endl;[/CODE]

But I was extremely surprised to find out that the average norm of body forces is of order ##10^7##, which is not even close to 0.

Question

I have two questions.

1. I am not expecting that any of you is familiar with the FreeFem++. If you are, even better, you can help me understand what I am doing wrong in my script.

2. Am I making wrong assumptions? Should I not be surprised that the divergence of the stress tensor is not zero? Is this not even a problem but rather an expected result? If yes, could you help me understand why?