maths85

- 6

- 1

Hello.

I need to calculate spur gear transmissions.

I need a bit of guidance for the first steps.

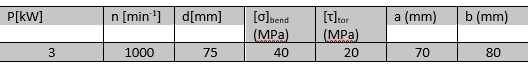

The data is the next:

n= 1000 rev/min

Mt torque= 28.65 Nm

i transmission ratio= 4

P load in the shaft= 3kW

I am a bit lost to star selecting the material (depending the load and work conditions).

The strees of the transmissions and the module of the gears.

I understand that I need to check the material in a catalogue of materials. But honestly I am lost trying to select the right one and fail at the beginning of my calculation of gears.Later on when I have to calculate the module, which date should I set as I random number, the number of teeth then I will be able to calculate the module later.

Thank you.

I need to calculate spur gear transmissions.

I need a bit of guidance for the first steps.

The data is the next:

n= 1000 rev/min

Mt torque= 28.65 Nm

i transmission ratio= 4

P load in the shaft= 3kW

I am a bit lost to star selecting the material (depending the load and work conditions).

The strees of the transmissions and the module of the gears.

I understand that I need to check the material in a catalogue of materials. But honestly I am lost trying to select the right one and fail at the beginning of my calculation of gears.Later on when I have to calculate the module, which date should I set as I random number, the number of teeth then I will be able to calculate the module later.

Thank you.