- #1

Mark111

- 8

- 0

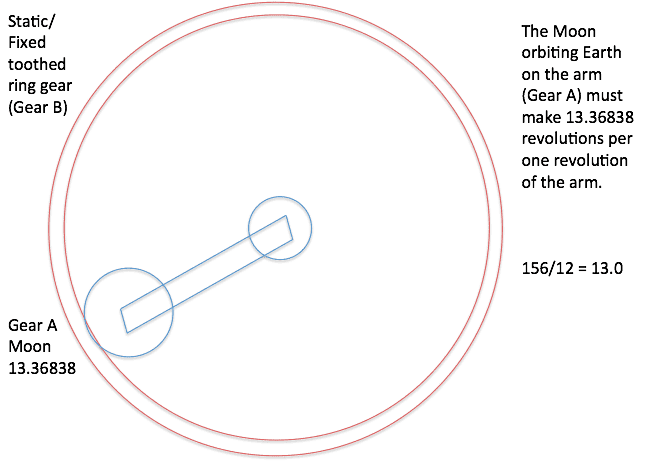

Hello Ladies and Gents,I am look for some help with designing the gear trains for an orrery (a mechanical model of the solar system) I am planning. I need some advice on how to go about calculating the specification of the gears in the mechanism which I will machine. I will use cycloidal teeth I am struggling to understand the relationship between the gear ratio; which I understand to be the "ratio of the angular velocity of the input gear verses the angular velocity of the output gear" and the number of teeth a gear must possesses to honour that ratio. I can’t find a clear explanation of how to determine the appropriate number of teeth a gear must possesses to honour a specific ratio. All of the examples on the Forum have a known number of teeth on one or more of the gears in the train. For example:As in the diagram below; I need the gear that drives the moon (GEAR A) to rotate 13.36838 times per 1 revolution it makes of the fixed ring gear – but how many teeth do I need to reach this outcome. I can guess that 12 teeth on the moon gear and 156 teeth on the fixed ring gear will cause 13.0 revolutions of the moon gear per 1 revolution the arm makes of the fixed ring gear…But this does not get me to the 13.36383 revolutions I need and nor do I find this method repeatable for more complex/less favourable ratios.What is/is there a formulaic method to calculate exact gear ratio into teeth counts?

Many thanks for assistance rendered.

Many thanks for assistance rendered.