LeeKimbo

- 1

- 0

How did you find PF?: Google search

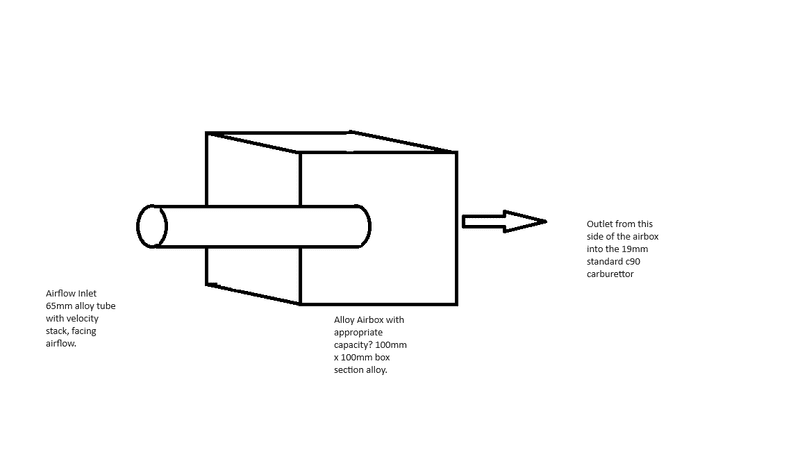

Hello everyone, thanks for letting me join. I am hoping that some of you would be intrigued and help me design a new motorcycle airbox for a charity moped racing series here in the UK. We take the most common motorcycle ever made the Honda c90 and race it for 7 or 8 hours around race tracks to get the most laps done against other like minded teams. All of which raises money for charity such as Blood Bikes and Air Ambulances. The motorcycle engine is a big bore 110cc single cylinder 4 stroke, two valve which is fed by a 19mm standard c90 carburettor. the maximum rpm is 10500 and it is currently using the standard airbox which was designed for economy and for an 86cc cylinder. As the object is to do the most laps, we therefore need to get the most performance from the engine in a reliable way.

As I understand the basics the airbox volume should be between 10x and 20x the capacity and currently the one fitted is under this. I also want to feed this with a direct forward facing air intake of 65mm diameter pipe facing directly into the airflow. When riding the bike speed is from

40mph to 70mph to try and maximise the air through the carb. the carb is a fixed aspect to standardise the bikes so cant be changed.

Can anyone advise me on what would be the best capacity to build for the airbox volume to maximise the incoming airflow to create the best resonance or performance from the engine please. Our bike is not the fastest on the grid and i'd like to become more competitive as its a great fund series to be involved in. The questions I have are:

1. what would be the optimum volume of the airbox for this capacity of engine and rpm?

2. The inlet is currently 65mm tube going directly into the airbox at the side, is this big enough / too big / too long?

3. Are there any suggestions on modifying this sketch to improve the airbox and consequently the performance of the bike?

4. Will the direct airflow into this sealed box at the airspeed indicated improve the airflow through the carburettor?

5. Should there be any interior baffles or deflector plates inside the airbox (which is completely empty apart from the inlet and outlet in the centre at the back (right side end face) on this design.

I hope this is not too difficult to shed some light on for me and I appreciate anything and everything that this forum could contribute. Please fire away with any questions and I'll do my best to answer. Many thanks in advance!

Hello everyone, thanks for letting me join. I am hoping that some of you would be intrigued and help me design a new motorcycle airbox for a charity moped racing series here in the UK. We take the most common motorcycle ever made the Honda c90 and race it for 7 or 8 hours around race tracks to get the most laps done against other like minded teams. All of which raises money for charity such as Blood Bikes and Air Ambulances. The motorcycle engine is a big bore 110cc single cylinder 4 stroke, two valve which is fed by a 19mm standard c90 carburettor. the maximum rpm is 10500 and it is currently using the standard airbox which was designed for economy and for an 86cc cylinder. As the object is to do the most laps, we therefore need to get the most performance from the engine in a reliable way.

As I understand the basics the airbox volume should be between 10x and 20x the capacity and currently the one fitted is under this. I also want to feed this with a direct forward facing air intake of 65mm diameter pipe facing directly into the airflow. When riding the bike speed is from

40mph to 70mph to try and maximise the air through the carb. the carb is a fixed aspect to standardise the bikes so cant be changed.

Can anyone advise me on what would be the best capacity to build for the airbox volume to maximise the incoming airflow to create the best resonance or performance from the engine please. Our bike is not the fastest on the grid and i'd like to become more competitive as its a great fund series to be involved in. The questions I have are:

1. what would be the optimum volume of the airbox for this capacity of engine and rpm?

2. The inlet is currently 65mm tube going directly into the airbox at the side, is this big enough / too big / too long?

3. Are there any suggestions on modifying this sketch to improve the airbox and consequently the performance of the bike?

4. Will the direct airflow into this sealed box at the airspeed indicated improve the airflow through the carburettor?

5. Should there be any interior baffles or deflector plates inside the airbox (which is completely empty apart from the inlet and outlet in the centre at the back (right side end face) on this design.

I hope this is not too difficult to shed some light on for me and I appreciate anything and everything that this forum could contribute. Please fire away with any questions and I'll do my best to answer. Many thanks in advance!