Kaeros

- 2

- 0

My issue is related to the actual flow-rate I obtain when sampling air across a filtering membrane.

Each pump reports a nominal amount of air that it can draw in a certain amount of time (i.e.: flow-rate, like 10 liters per minute), but this is generally reported assuming normal temperature and pressure and with no "load" applied to the pump.

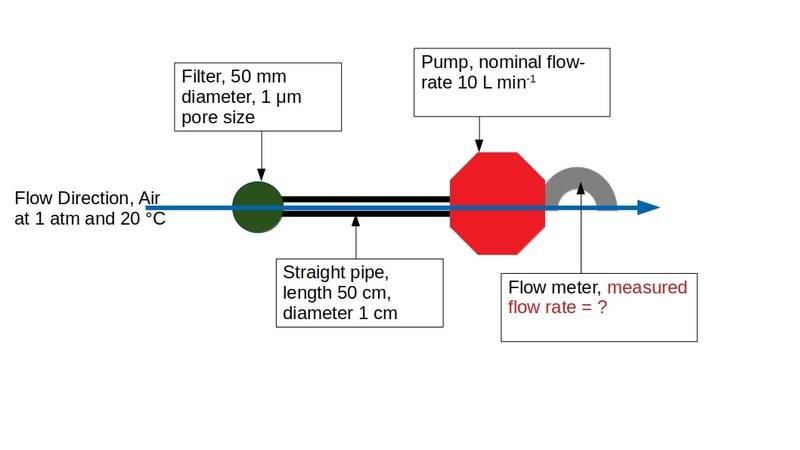

Let's assume now that I attach to the inlet of the pump 50 cm of a straight pipe with a known diameter (let's say 1 cm) and on top of that an open faced filter holder with a filter with given diameter (50 mm) and porosity (let's say 1 micron pore size).

Let's assume that we turn on the system at ground level in normal conditions (so that the air that the pump is sucking in through the filter is at 1 atm and 20 °C): what would be the actual flow-rate that I would measure with a flow-meter at the outlet of my pump? How can I compute that?

Each pump reports a nominal amount of air that it can draw in a certain amount of time (i.e.: flow-rate, like 10 liters per minute), but this is generally reported assuming normal temperature and pressure and with no "load" applied to the pump.

Let's assume now that I attach to the inlet of the pump 50 cm of a straight pipe with a known diameter (let's say 1 cm) and on top of that an open faced filter holder with a filter with given diameter (50 mm) and porosity (let's say 1 micron pore size).

Let's assume that we turn on the system at ground level in normal conditions (so that the air that the pump is sucking in through the filter is at 1 atm and 20 °C): what would be the actual flow-rate that I would measure with a flow-meter at the outlet of my pump? How can I compute that?