Colin Wilson

- 12

- 6

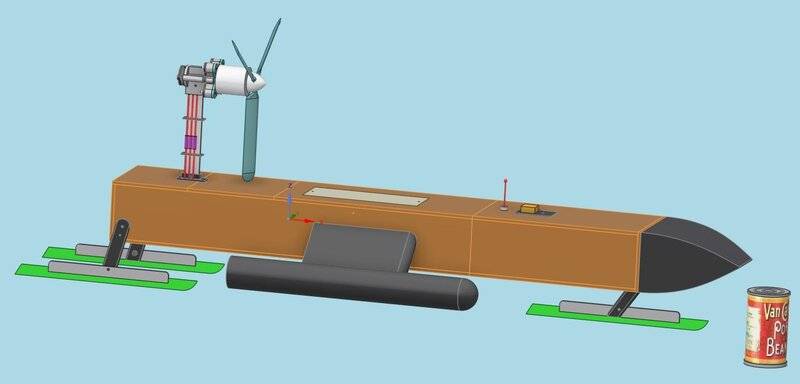

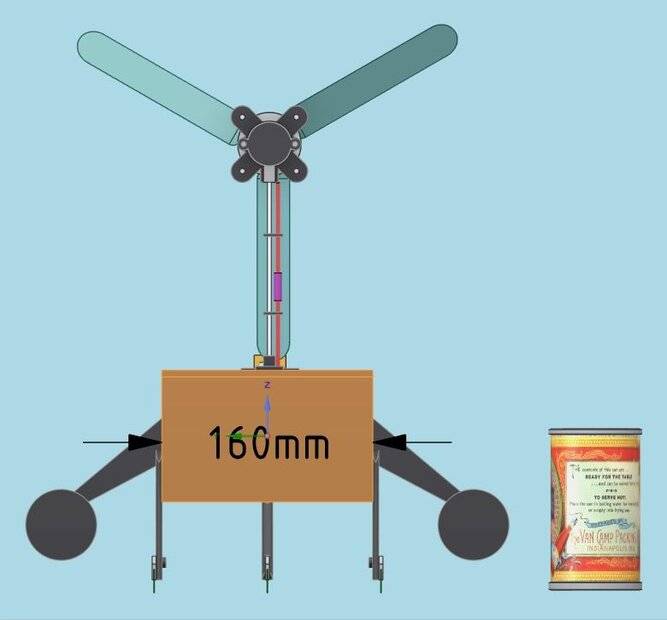

I'm building a model as shown below (side, front, back). In order to measure its air resistance I will be mounting it on temporary ice blades (Green) and driving it down a long skating rink. The model has a pressure sensor incorporated into the motor / propeller assembly and a GPS unit to measure velocity, a microcontroller collects the data (pressure / velocity) and writes it to an SD card. As it sits the blade loading would be as follows:

- (3) SS blades = 30cm long * 1mm thick

- Top speed 90kph (82fps)

- Loading 2kg per blade = 0.67kg / cm2