josephd

- 2

- 1

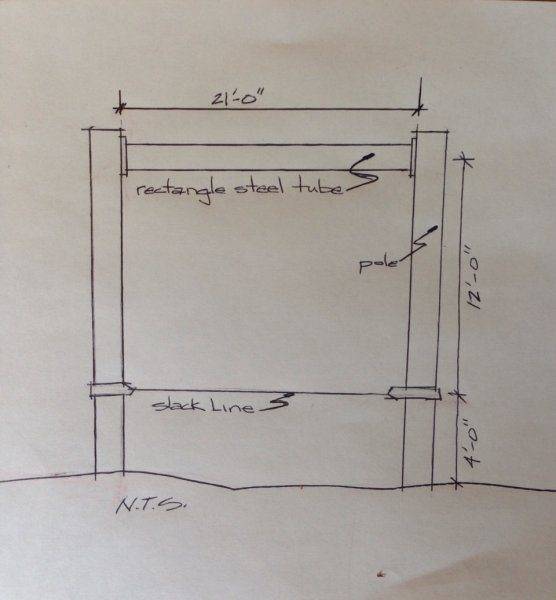

I am trying to complete a project and have to properly size some steel tubing. The project is a belay bar for a slackline we have in the yard.

I have 2 poles that are set in the ground 21' apart and a slackline runs between them. We want to run a steel tube beam, permanently attached to the posts, that will act as structure to attach a belay line to the kids in case they fall off.

Ive attached a sketch of the set-up. The belay line will attach around the tube and to a harness the kids wear.

I'm figuring the max load at 500lbs and max fall distance at 18". I'm not sure I've given all the info needed but I do appreciate any help.

My question is what size tubing do we need and what shape would work best?

I have 2 poles that are set in the ground 21' apart and a slackline runs between them. We want to run a steel tube beam, permanently attached to the posts, that will act as structure to attach a belay line to the kids in case they fall off.

Ive attached a sketch of the set-up. The belay line will attach around the tube and to a harness the kids wear.

I'm figuring the max load at 500lbs and max fall distance at 18". I'm not sure I've given all the info needed but I do appreciate any help.

My question is what size tubing do we need and what shape would work best?