RonL

Gold Member

- 1,107

- 219

OmCheeto said:A Cessna? Talk about thinking inside the box...

I was thinking more on the line of meshing and morphing the technologies of the desired attributes of existing electric vehicles:

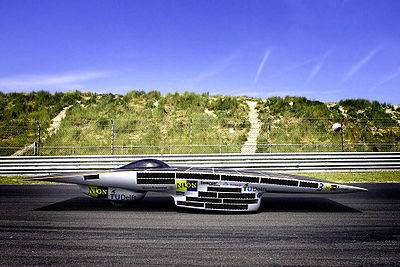

Speed:

105 mph. Batteries not included.

Altitude:

96,863 feet

Range: Lots of range on most vehicles. Though there are none that have both range and speed.

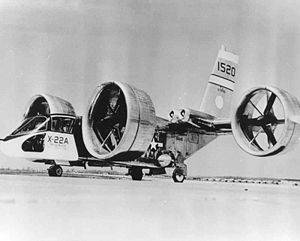

Rings? This one has lots of rings:

But seriously, I would imagine, based on the the Nuna and Helios examples above, that the most efficient and likely candidate to win the race would be some sort of flying wing.

Kind of like this little fella:

Only not quite so thick. I don't think we need to be carrying around 40,000 lbs of bombs.

All fine examples, and I love flying wings.

When I talk about outside the box, I'm generally thinking about things that can be done at my time and financial level, which is pretty small.

About the picture of the ring ducts, that is quite like what I was trying to describe only what I picture is smaller and not as bulky looking. Now if you can see in the minds eye those rings as part of the prop and in spin motion, they will store energy like a flywheel and I might dare say the drag of air flowing around and through them will be less than if motionless (?)

What I think to be most outside the box, is what happens at the motor/generator section.

If the housing and armature are allowed to spin in opposite directions twice the voltage (or more) can be applied, and if cooling based on air velocity will allow, the amp load might be doubled, you then have 4 times the power being applied between the two props.

The power being supplied is from batteries and is in modified wave form (or pulses).

The instant of change from power being supplied to power being generated, the load against the motor action being minus, becomes positive to the generator action and goes to the batteries in a continuous flow.

This might be just a very small difference, but something to look at.

Only electrical control can take advantage of those thermals you mentioned

The power switches happen in microseconds and changes in speed and rotating mass will have almost no change.

This is completely different than something bolted to a shop table.

Ron

I can see how the words didn't make for a clear picture.

I can see how the words didn't make for a clear picture.