Butters

- 75

- 1

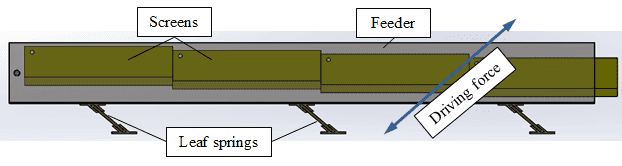

I have created such vibrating feeder model on SW but on ANSYS I'm only analyzing the frame.

1)How do I set up boundary conditions, I think I need elastic supports?

2)In modal analysis I have elastic, fixed supports, remote displacement - which should I use and in what directions?

3)Do I perform modal analysis with the screens or without?

4)Is there any way to input frequency parameters and find out fatigue?

1)How do I set up boundary conditions, I think I need elastic supports?

2)In modal analysis I have elastic, fixed supports, remote displacement - which should I use and in what directions?

3)Do I perform modal analysis with the screens or without?

4)Is there any way to input frequency parameters and find out fatigue?

Last edited: