Discussion Overview

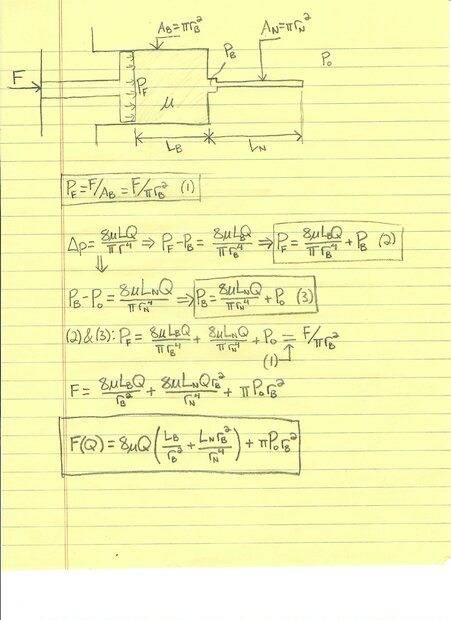

The discussion revolves around calculating the force required to operate a syringe plunger for dispensing a viscous fluid, specifically glue or resin. Participants explore the relationship between flow rate, fluid viscosity, and the geometry of the syringe and needle, utilizing the Poiseuille equation as a basis for their calculations.

Discussion Character

- Technical explanation

- Mathematical reasoning

- Debate/contested

Main Points Raised

- One participant derives a force equation based on the Poiseuille equation, questioning the validity of combining two pipe sections in their calculations.

- Another participant suggests that while applying Poiseuille's law to the needle is appropriate, the flow behavior in the syringe barrel may not conform to Poiseuille flow due to flow contraction.

- Concerns are raised about the impact of flow acceleration on pressure, with a suggestion to consider dynamic pressure in the calculations.

- Participants discuss the significance of the pressure drop in the needle, with one noting that atmospheric pressure cancels out in the calculations.

- Details about the viscosity of the resin and the dimensions of the syringe and needle are shared, with specific values provided for viscosity and expected flow rates.

- One participant updates their calculations to exclude atmospheric pressure, resulting in a force estimate that varies with different flow rates.

- There is a request for confirmation on whether shear rate calculations align with the derived force values from the Poiseuille equation.

Areas of Agreement / Disagreement

Participants express differing views on the applicability of the Poiseuille equation to the syringe barrel and the influence of dynamic pressure. While some agree on the importance of the pressure drop in the needle, there is no consensus on the overall accuracy of the initial calculations or the treatment of atmospheric pressure.

Contextual Notes

Limitations include potential inaccuracies in applying Poiseuille flow assumptions to the syringe barrel, the need for further exploration of dynamic pressure contributions, and the dependence on specific fluid and syringe parameters.

Who May Find This Useful

This discussion may be of interest to those involved in fluid dynamics, engineering applications related to syringe design, or anyone working with viscous fluids in dispensing systems.